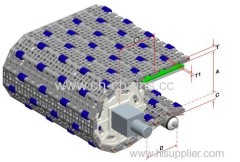

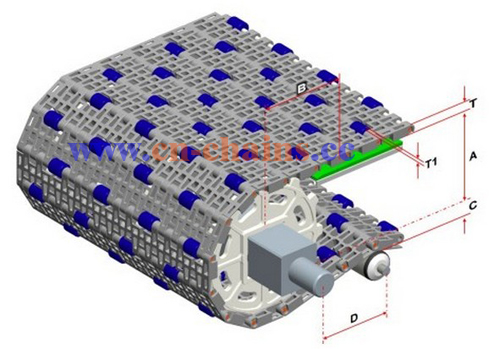

M5032 Roller Top Modular plastic conveyor belt for transportation lines

| Min. Order: | 15 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 1000 suquer meters a mouth |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Plastic Belt Conveyor, Perforated Flat Top Modular Belt Conveyor, Flat Top Belt Conveyor, Industrial Conveyor Belt, Food Conveyor Belt |

Product Detail

| Model No.: | RW-YY-M5032 |

|---|---|

| Means of Transport: | Ocean, Air |

| Structure: | Belt Conveyor |

| Material: | Plastic |

| Material Feature: | Heat Resistant |

| Brand Name: | OEM |

| Material: | POM / PP |

| Open Area: | 33% |

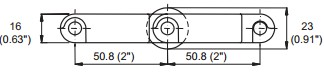

| Pitch: | 50.8 mm |

| Rod Diameter:: | 7mm |

| Thickness:: | 16mm |

| Curve: | No |

| Color: | Gray |

| Application: | manufacturing |

| Place of Origin: | Zhejiang China (Mainland) |

| Export Markets: | North America, South America, Eastern Europe, Southeast Asia, Oceania, Mid East, Western Europe |

| Production Capacity: | 1000 suquer meters a mouth |

| Packing: | by carton |

| Delivery Date: | 13-18days |

Product Description

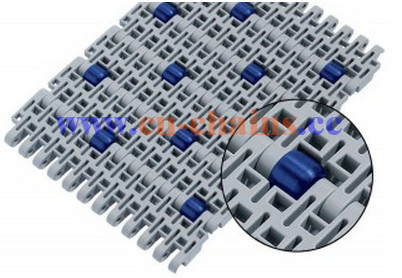

modular plastic roller insert into the belts

Belt material

| PP | POM | |||||

Rod material

| PP | PA | |||||

Roller material | POM | ||||||

Width | mm in | 18 0.71 | 18 0.71 | 18 0.71 | 18 0.71 | 18 0.71 | 18 0.71 |

Weight | Kg/m2 Lb/sqft | 8.0 1.64 | 8.0 1.64 | 8.0 1.64 | 8.0 1.64 | 12.0 2.64 | 12.0 2.64 |

Temperature range | °C

°F | 5-93

40-200 | 5-93

40-200 | 5-93

40-200 | 5-93

40-200 | -40-93

-40-200 | -40-93

-40-200 |

Payment & Shipping Terms | Supply Capacity | ||

Unit Price: | 75.0~100.0 USD | Production Capacity: | 1000 square meter/month |

Payment Term: | T/T,Western Union | Packing: | carton |

MOQ: | 15square Meter | Delivery Date: | 13-18days |

Means of Transport: | Ocean, Air | ||

Description

1,Strong design

2.For low back pressure, wearstrips are placed between

rollers

3.For product driven application wearstrips are placed

4.directly under the rollers

5.Excellent for flushing and draining

6.Closed hinge

7.Food approved materials available

Plastic belt is the use of engineering plastics production chain plate assembly made of modular belt with interlocking brickway interleaved mode or by the total length of the pin assembly together, this design is fundamentally improve the conveyor belt strength.Flights and

side panels can also be interlocked with the

hinge pin has become integral parts of the conveyor belt. Plastic belt has too much forms, assembling flexible, easy to replace. There are openings in the form,

flat, ribs, ball, slip and other forms. Apply to pigs, sheep, chickens, ducks slaughtered , cutting and processing, puffed food production line, fruit grading,

packing lines, fish processing production line, frozen food production line, battery manufacturing, beverage manufacturing, canning industry, agro-

industry, chemical industry , electronics, rubber and plastic manufacturing industry, the cosmetics industry, the general transport operations

Advantage

Precision molding process ensures optimum flatness.

High wear resistance and low friction coefficient

High work load

Food plastic mesh belt characteristics: corrosion resistance, oxidation resistance, wear resistance, light weight, resistance to acid and alkali, high

temperature resistant, pull big, long life and other characteristics;Material: POM, PP, PE;Widely used in food industry, tire and rubber conveyor industry,

daily chemical industry, papermaking industry, beverage manufacturing workshop assembly for use under different working environment;We have

advanced equipment, mature technology, reasonable price and high quality products to provide customers with sincere service, meet the needs of

customers is our goal

Conveyor belts in use should note the following

1.Avoid roller is covered with material, resulting in ineffective rotation to prevent leakage of material between the roller and the tape card, pay attention to the lubrication of moving parts,

2.Avoid starting with a over load

Ningbo Rellwin industry Co., Limited is specialized in manufacture

900 Flush Grid plastic modular conveyor belt,900 Raised Rib plastic modular conveyor belt,900 Flat Top plastic modular conveyor belt

1100 Flush Grid plastic modular conveyor belt,1100 Flat Top plastic modular conveyor belt

OPB modular conveyor belt,OPB Flat Top plastic modular conveyor belt,OPB Flush Grid plastic modular conveyor belt,OPB Flight modular conveyor belt,

5936 Flush Grid plastic modular conveyor belt,5930 Raised Rib plastic modular conveyor belt,5935 Flat Top plastic modular conveyor belt

400 Flush Grid plastic modular conveyor belt,400 Raised Rib plastic modular conveyor belt,400 Flat Top plastic modular conveyor belt,

1000 Flush Grid plastic modular conveyor belt,1000 Raised Rib plastic modular conveyor belt,1000 Flat Top plastic modular conveyor belt

M-SNB-M2 Flat Top plastic modular conveyor belt,M-SNB-M3 Flush Grid plastic modular conveyor belt

L-SNB Flush Grid plastic modular conveyor belt,L-SNB Raised Rib plastic modular conveyor belt

4809 Raised Rib plastic modular conveyor belt

A modular conveyor belt, which is capable of flexible running and assembly of a plurality of rows of plastic belt modules in the form of modules.Rows of

conveyor belt modules connected by a connecting pin extending along a hinge line with the pin passing through the end of the chain conveyor belt module

as an opening, the opening extending in the longitudinal direction of travel, the adjacent rows of modules the chain ends are staggered,Among them:

Longitudinal direction from the end of conveyor module conveyor extending in the conveying end of the conveyor chain has a slot opening for receiving a

connecting pin conveyor, in each module, the chain conveyor comprises a front end and a rear end of the chain terminal group group wherein one low

chain end groups are in a higher position, and the other in the lower position, the delivery module is assembled and staggered, so that one end of the

module row of high amylose and high chainend connected rows of adjacent modules, and a module row conveyor connected to the low end of the chain

of another module adjacent rows located at the inside of a turn in the road in turn transport conveyor modules together shrinkage, high chain-end along

a first direction extending in the forward or backward adjacent the upper end of the lower strand of the next module row also extending in the first direction

along a conveying module adjacent to the top by overlapping therewith, the delivery conveyor at the high end of the chain adjacent to the next module in the

row of connecting pins, so that with the turning of the inner edge close to shrink.

Our services

1. Warranty time: 1 year. The conveyor belt / chains / sprockets which supplied by our company could be exchanged when it have quality problems,such as it was broken in installing , the pin run out from chains or the chains parted . But if the user use it in a wrong way, we can not provide any goods for free .

2. Payment: T/T , L/C , Western Union or Paypal .

3. Lead time: 5~15 working days, subject to the order quantity.

4. Shipment: by sea, by air,door to door service for samples transportation.

5. OEM service : we have our own R.D team . If you want to purchase the belt which we have not or you have your own design , we would like to make mold for you for free , only have the condition of requiring continuous orders ,and first order must be more than 60 square meters .

Company and Productsinformationrelated:

Ningbo Rellwin IndustryCo.,ltd