Flush Grid M1230 Plastic Modular conveyor Belts for food industry

| Min. Order: | 15 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 2000 suquer meters a mouth |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Plastic Belt Conveyor, Perforated Flat Top Modular Belt Conveyor, Flat Top Belt Conveyor, Industrial Conveyor Belt, Food Conveyor Belt |

Product Detail

| Model No.: | RW-YY-M1230 |

|---|---|

| Means of Transport: | Ocean, Air |

| Structure: | Belt Conveyor |

| Material: | Plastic |

| Material Feature: | Heat Resistant |

| Brand Name: | OEM |

| Material:: | POM / PP |

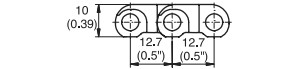

| Belt Pitch: | 12.7mm |

| Open area: | 18% |

| Open contract area: | 70% |

| Backflex radius: | 25mm |

| Thickness: | 10mm |

| Rod Diameter:: | 5mm |

| Function: | Conveyor |

| ISO certificate: | ISO9001:2000 |

| Export Markets: | North America, South America, Eastern Europe, Southeast Asia, Oceania, Mid East, Western Europe |

| Production Capacity: | 2000 suquer meters a mouth |

| Packing: | by carton |

| Delivery Date: | 13-18days |

Product Description

Flush Grid conveyor belt M1230 on sale

plastic conveyor belting Flush grid 1230 manifacturer

straight running conveyor beltings M1230

Sprockets for 1200series

Belt material

|

PP

|

PE |

POM | ||

Rod material

| PP | PE | PP | PA | |

Working load | N/M Lb/ft | 11000 753 | 7000 480 | 16000 1069 | 18000 1233 |

Weight | Kg/m2 Lb/sqft | 5.4 1.11 | 5.7 1.17 | 7.8 1.60 | 7.8 1.60 |

Temperature range | °C

°F | 5-105

40-220 | -70-65

-94-150

| 5-93

40-200

| -40-93

-40-200 |

Payment & Shipping Terms | Supply Capacity | ||

Unit Price: | 100.0~85.0 USD | Production Capacity: | 2000 square meter/month |

Payment Term: | T/T,Western Union | Packing: | carton |

MOQ: | 15 square Meter | Delivery Date: | 13-18days |

Means of Transport: | Ocean, Air | ||

Product Description

Belt Type: M1230

Belt Material: POM/PP/PE

Belt Pitch: 12.7mm

Open area: 18%

Assembling method: Connected with rods

• "Nosebar transfer", recommended diameter 18 mm

(0.71"); 16 mm (0.63") possible

• 18% open area; 70% open contact area; largest

opening 5x3.3 mm (0.2"x0.13")

• Stiff 0.5" Flush Grid design

• Open hinge

• Food approved materials available

• Rod diameter 5 mm (0.2")

• "Open window" sprockets

We have advanced equipment, mature technology, reasonable price and high quality products to provide

customers with sincere service, meet the needs of customers is our goal

Our company has been qualified with ISO 9001:2000 quality system. The production strictly complies with the

standard and procedures of ISO 9001, which ensures good product quality.

If you are interested in ourproducts, please feel free to contact us.

Plastic belt is the use of engineering plastics production chain plate assembly made of modular belt with interlocking brickway interleaved mode or by the total

length of the pin assembly together, this design is fundamentally improve the conveyor belt strength.Flights and side panels can also be interlocked with the

hinge pin has become integral parts of the conveyor belt. Plastic belt has too much forms, assembling flexible, easy to replace. There are openings in the form,

flat, ribs, ball, slip and other forms. Apply to pigs, sheep, chickens, ducks slaughtered , cutting and processing, puffed food production line, fruit grading,

packing lines, fish processing production line, frozen food production line, battery manufacturing, beverage manufacturing, canning industry, agro-industry,

chemical industry , electronics, rubber and plastic manufacturing industry, the cosmetics industry, the general transport operations

Advantage

Precision molding process ensures optimum flatness.

High wear resistance and low friction coefficient

High work load

Transportation and daily maintenance of plastic belt

1.During storage, the product must be placed into a roll not folded, turning once during placement should be on a quarterly basis

2.Different type, size layers together using the belt should

3.Type conveyor belt, structure, size, number of layers should be a reasonable choice according to the conditions

4.Feed direction along the direction of the tape should be, in order to reduce the impact on the whereabouts of the tape should be taken when the material

chute, reducing materials falling distance

Conveyor belts in use should note the following

1.Avoid roller is covered with material, resulting in ineffective rotation to prevent leakage of material between the roller and the tape card, pay attention to the lubrication of moving parts,

2.Avoid starting with a over load

Company Name: Rellwin Industry Co., Limited

Or name:Ningbo Rellwin industry Co., Limited.

Located in the Port city ------ NINGBO

Business range ----- a variety of plastic chains/modular plastic belts /conveyer accessories and so on

(Our factory)Histry in domestic market: Around 20 years

History in foreign trade: More than 3years

Rellwin industry Co., Ltd is specialized in developing and manufacturing a variety of plastic chains, modular plastic belts and conveyor accessories.

Through the ongoing R&D, we have own design team ,professional machine and processing equipment and so on.. OEM&ODM service is our feature ,

High quality and short delivery time is the customers of our evaluation.

We provide worldwide customers with a full line of reliable products:

1, Automatic Vertical Packing Machine

Suitable for measuring and packing anomalous lumpish and granule materials, such as candy, popped food, biscuit, roasted seeds and nuts, granulated

sugar, deep-frozen food, milk powder, milk tea, amylum, sauce and so on.

2, Automatic label sleeving machine

Such as Shrink Film Labeling Machine, Adhesive-tape labeling machine

And Hot Melt Adhesive Labeling machine

3, Conveyor

Such as top chains type conveyor, functional modular net chains type conveyor, screwy type conveyor. Bucket lifter, clamping lifter, belt and roller conveyors.

Our products are widely used in such machinery industries as alcoholic and beverage, food & cold food, tobacco, (pillow-type) packaging, chemicals,

pharmacy, cosmetic, bottle-making, jar-making, post & telecommunication, and painting engineering

4, Conveyor chains & components

Such as steel chains, plastic top chains, functional mould netting chains, conveyor components, sprockets, corner tracks, roller, screw track, star wheels

and wearstrips.

Our services

1. Warranty time: 1 year. The conveyor belt / chains / sprockets which supplied by our company could be exchanged when it have quality problems,such as it was broken in installing , the pin run out from chains or the chains parted . But if the user use it in a wrong way, we can not provide any goods for free .

2. Payment: T/T , L/C , Western Union or Paypal .

3. Lead time: 5~15 working days, subject to the order quantity.

4. Shipment: by sea, by air,door to door service for samples transportation.

5. OEM service : we have our own R.D team . If you want to purchase the belt which we have not or you have your own design , we would like to make mold for you for free , only have the condition of requiring continuous orders ,and first order must be more than 60 square meters .

Company and Productsinformationrelated:

Ningbo Rellwin IndustryCo.,ltd.