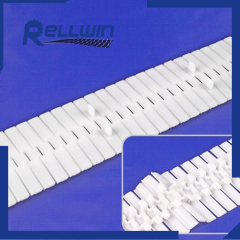

Table Top chain belt conveyor plastic flexible 880STAB mini

| Min. Order: | 30 Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, L/C, T/T, WU, Money Gram |

| Supply Ability: | 1000 meter a mouth |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Plastic Belt Conveyor, Perforated Flat Top Modular Belt Conveyor, Flat Top Belt Conveyor, Industrial Conveyor Belt, Food Conveyor Belt |

Product Detail

| Model No.: | RW-880STAB mini |

|---|---|

| Means of Transport: | Ocean, Air |

| Material Feature: | Heat Resistant |

| Material: | Plastic |

| Structure: | Chain Conveyor |

| Brand Name: | OEM |

| Plate width:: | 120.5mm |

| Weight:: | 1.60kg/m |

| Pitch:: | 19.05mm |

| Thickness:: | 7mm |

| Pin Material:: | SUS304 |

| Sideflex Radius(min):: | 610mm/24inch |

| Backflex Radius(min):: | 50mm / 1.97inch |

| Sample: | for free |

| Color:: | any color |

| Packaging:: | carton |

| Production Capacity: | 1000 meter a mouth |

| Packing: | by carton |

| Delivery Date: | 10-15days |

Product Description

sideflexing conveyor chains

Plastic modular conveyor chain 880

Flat top modular conveyor chain manufacturers

plastic modular Spiral chains

Description

• Radius running plastic tab chain

• Thick top plate = longer wear life

• For side transfer with 821 and 831 series straight running chains

advantage |

1.With ISO9001 |

2.Factory quantity |

3.Design as your required |

4.Have our technical team |

Plastic tabletop chains are made of engineering plastic and are connected using stainless steel pins. The plastic tabletop chains constitute a light-weight yet strong and silent alternative to steel chains.

These chains are used mainly in the food and packaging industry for conveying many kinds of containers. For example:PET bottle,PET petaloid bottle,Aluminum and steel can, Cartons, Trays,Packaged products (cartons,shrink packs),Glass, Plastic containers.

Accuracy of molding process guarantees optimum flatness

High wear resistance and low friction

High working load

Specifications

1.Excellent wear resistance

2.Lower cofficient of friction

3.High productivity of combiners

4.FDA Grade

Applications:

1.Food and beverage industry,conveying lines for PET bottles,aluminium cans and Steels cans. Packaging lines (PET bottle packs in heat shrink film,paper board boxes cans in heat shrink film).

2.Pharmaceutical industry

3.General purpose conveying applications.

Transportation and daily maintenance of plastic conveyor chain

During storage, the product must be placed into a roll not folded, turning once during placement should be on a quarterly basis

2.Different type, size layers together using the chain should

3.Type conveyor chain, structure, size, number of layers should be a reasonable choice according to the conditions

4.Feed direction along the direction of the tape should be, in order to reduce the impact on the whereabouts of the tape should be taken when the material chute, reducing materials falling distance

Conveyor chain in use should note the following

1.Avoid roller is covered with material, resulting in ineffective rotation to prevent leakage of material between the roller and the tape card, pay attention to the lubrication of moving parts,

2.Avoid starting with a over load

Feature of Plastic modular conveyor chain

Plastic modular conveyor flexiblechain using chain injection splicing, and with supporting the drive sprocket, with no deviation drive replacement easier cleaning

characteristics.Plastic mesh chain drive module is stuck in the chain sprocket sprocket grooves are opposite the corresponding drive, so no deviation.Plastic

modular conveyor chain is easier to replace because it is wearing a matching pin assembled, it can be based on partial replacement of damaged parts, it is

unnecessary to replace the whole one , to save a certain amount of expenses.Plastic modular chain is relatively flat and smooth surface, can be directly rinsed with

water and wash with some tools.Plastic materials have arbitrarily chosen to achieve and satisfy the conditions customers, there are food-grade plastic chain and

high temperature plastic mesh and plastic mesh chain wear and rally.Is a new type of environmentally friendly technology conveyor ideal supplies. Plastic mesh is

also called plastic modular chain chain is the introduction of foreign advanced technology, using molds for injection molding and then stitched together according

to customer demand.

Trade Terms:.

1. Payment By T/T or Western Union or Paypal.

100% payment if the total amount is less than USD 500.00

2. Lead time: 5~15 working days, subject to the order quantity.

3. Delivery ways: by sea, by air . DHL , UPS door to door service for samples transportation ,

4. Free sample: 2pcs

Our service:

1. Reply your enquiry in 24 working hours

2. Experienced staffs answer all your questions in fluent English/

3. Customized design is available, OEM&ODM are welcomed

4. Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staffs.

5. Special discount and protection of sales area provided to our distributor.

Company and Products information related:

Ningbo Rellwin Industry Co.,ltd.