Flat top straight running high speed modular conveyor belt (RW FT-MQNB)

| Min. Order: | 20 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 150 square meter/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Plastic Belt Conveyor, Perforated Flat Top Modular Belt Conveyor, Flat Top Belt Conveyor, Industrial Conveyor Belt, Food Conveyor Belt |

Product Detail

| Model No.: | RW FT-MQNB |

|---|---|

| Means of Transport: | Ocean, Air |

| Structure: | Belt Conveyor |

| Material: | Plastic |

| Material Feature: | Others |

| Brand Name: | OEM |

| Material: | POM / PP / PE |

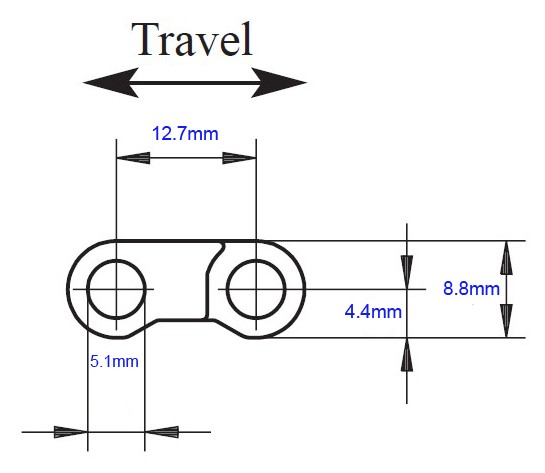

| Pitch: | 12.7mm / 0.5inch |

| Open area:: | 0% |

| Backflex Radius(min.): | 20mm |

| Color: | white / blue / grey |

| Belt Width: | 76mm , N*76mm |

| Assembling method: | connected with rods |

| Thickness: | 8.8mm |

| Belt bore Diamater: | 5.1mm / 0.20inch |

| Pin diameter: | 5.0mm / 0.20inch |

| Production Capacity: | 150 square meter/month |

| Packing: | carton |

| Delivery Date: | 19-28days |

Product Description

RW MQNB – the high speed and tight transfer belt

The Mini QNB is a belt developed for tight transfer and high speed conveyors in both food

and non food industries. The 0.5 in. pitch, bi-directional belt ensures product stability even in nose bar and high speed.

Applications due to the rounded bottom surface.

The MQNB belt increases performance in the following industries/applications:

- Bakery applications including dough handling, general conveyance and packaging lines

- Meat applications including tray pack lines and metal detectors

- Seafood applications including grading lines and weighing lines

- Beverage applications including depalletizers, accumulation tables and acceleration lines

- Can manufacturing applications including palletizers, mass handling and accumulation tables

- Corrugated applications including downstacker, corrugator take off, transfer car and WIP storage

Product features and operational benefits:

- Less vibration in high speed and nosebar applications

- Wear resistance in high speed applications with tight transfers

- Strong bi-directional belt for longer conveyors

- Unique locking system (lockpin) for easy maintenance

- Unique sprocket engagement reduces pulsation

- Unique Rubber Top eliminates wear and increases friction in incline or acceleration application

| Item NO. | Backflex Radius(min.) | Belt Weight | Working Load(max.) | |||||||

| POM | PP | PE | POM | PP | PE | |||||

| mm | Kg/m | N | lbf | N | lbf | N | lbf | |||

| RW FT-MQNB | 20.0 | 8.20 | 6.10 | 5.90 | 19000 | 1302 | 13000 | 891 | 800 | 548 |

Modular belts are constructed with modules molded from thermoplastic materials connected with soild plastic rods. Except for narrow belts (one complete module or less in width),all are built with the joints between modules staggered with those of adjacent rows in a "bricklayed" fashion. This structure can enhance transverse strength and it is easy for maintain.

The total plastic and cleanable design can solve the steel belts easily polluted.Now the cleanable design makes the belts very suitable for food industry area as well.Also there are be widely used in many other industries,such as container making,pharmaceutical and automotive,lines of battery and so on.

Rellwin company has a widely range of different material and structure belts. The range of Rellwin's modular belts varies from 3/8 inch small pitch straight running belts to 2inch pitch sideflexing belts,The most commonly used belt styles inclued:

Flat Top:suitable for a wide range of products,when a fully closed belt surface is preferred.

Flush Grid:commonly used in applications where drainage or airflow is desired.

Raised Rib:recommended in applications where product stability over transfers is a concern.

Friction Top:commonly employed on incline conveyors, where the elevation of product changes.Friction Top modular belts can be used up to an angle of 20 degrees,depending on the pack style and material.

Roller Top:used in a variety of low-pressure accumulation applications.

Perforated Flat Top:used when air flow and water flow are critical but the percentage of belt open area must remain low.

Other,less frequently used belt styles may better fit your special requirements:Open Grid,Nub Top(anti-stick),Cone Top(extra grip).

Our services

1. Warranty time: 1 year. The conveyor belt / chains / sprockets which supplied by our company could be exchanged when it have quality problems,such as it was broken in installing , the pin run out from chains or the chains parted . But if the user use it in a wrong way, we can not provide any goods for free .

2. Payment: T/T , L/C , Western Union or Paypal .

3. Lead time: 5~15 working days, subject to the order quantity.

4. Shipment: by sea, by air,door to door service for samples transportation.

5. OEM service : we have our own R.D team . If you want to purchase the belt which we have not or you have your own design , we would like to make mold for you for free , only have the condition of requiring continuous orders ,and first order must be more than 60 square meters .

Company and Productsinformationrelated:

Ningbo Rellwin IndustryCo.,ltd.