rubber top modular conveyor belt with flight (QNB rubber top)

| Min. Order: | 20 Square Meter |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 90 square meter/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Plastic Belt Conveyor, Perforated Flat Top Modular Belt Conveyor, Flat Top Belt Conveyor, Industrial Conveyor Belt, Food Conveyor Belt |

Product Detail

| Model No.: | RW-QNB rubber top |

|---|---|

| Means of Transport: | Ocean, Air |

| Structure: | Belt Conveyor |

| Material: | Plastic |

| Material Feature: | Heat Resistant |

| Brand Name: | OEM |

| Material for belt: | PP+rubber |

| Material for rod: | PP / PA |

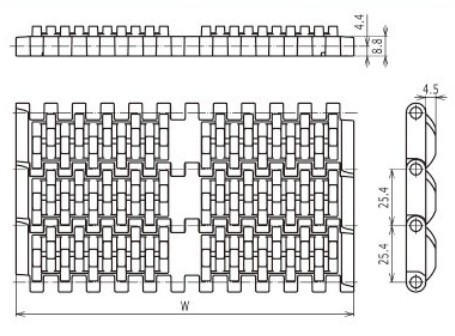

| Pitch: | 25.4mm/1.00inch |

| Width: | 152mm/6.0 inch |

| Backflex radius(min.): | 40mm |

| weight: | 8.0kg/m2 |

| Temperature range: | +5° to +66° |

| Working Loading(max.): | 2000N/m (21°) |

| Production Capacity: | 90 square meter/month |

| Packing: | carton |

| Delivery Date: | 19-28days |

Product Description

Modular belts are constructed with modules molded from thermoplastic materials connected with soild plastic rods. Except for narrow belts (one complete module or less in width),all are built with the joints between modules staggered with those of adjacent rows in a "bricklayed" fashion. This structure can enhance transverse strength and it is easy for maintain.

The total plastic and cleanable design can solve the steel belts easily polluted.Now the cleanable design makes the belts very suitable for food industry area as well.Also there are be widely used in many other industries,such as container making,pharmaceutical and automotive,lines of battery and so on.

Rellwin company has a widely range of different material and structure belts. The range of Rellwin's modular belts varies from 3/8 inch small pitch straight running belts to 2inch pitch sideflexing belts,The most commonly used belt styles inclued:

Flat Top:suitable for a wide range of products,when a fully closed belt surface is preferred.

Flush Grid:commonly used in applications where drainage or airflow is desired.

Raised Rib:recommended in applications where product stability over transfers is a concern.

Friction Top:commonly employed on incline conveyors, where the elevation of product changes.Friction Top modular belts can be used up to an angle of 20 degrees,depending on the pack style and material.

Roller Top:used in a variety of low-pressure accumulation applications.

Perforated Flat Top:used when air flow and water flow are critical but the percentage of belt open area must remain low.

Other,less frequently used belt styles may better fit your special requirements:Open Grid,Nub Top(anti-stick),Cone Top(extra grip).