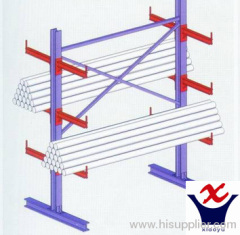

Warehouse cantilever rack

30.0~150.0 USD

| Min. Order: | 100 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5000sets/week |

| Place of Origin: | Shandong |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | XY-150 |

|---|---|

| Means of Transport: | Ocean |

| Type: | Cantilever Rack |

| Scale: | Heavy Duty |

| Brand Name: | XIAOYU |

| Capacity: | As per your requires |

| Material: | High quality steel |

| surface treatment: | powder coating |

| Certificate: | ISO 9001-2000 |

| Production Capacity: | 5000sets/week |

| Packing: | Export packing or as per your requires |

| Delivery Date: | Within 15 working days |

Product Description

Warehouse cantilever racking system/Cantilever shelving:

1.Cantilever rack can provide flexible storage and easy access to your non-pallet-sized material such as lumber, pipe, tubing, steel bars and furniture.

2.Cantilever rack is a freestanding storage unit with horizontal load carrying arms extending outward from a single vertical column. The absence of a front column makes cantilever rack faster and easier to load and unload than selective pallet rack, lowering your handling time and costs.

3.Available in single and double-sided configurations, cantilever rack is made of four basic components: towers, bases, arms and brace sets.

4.Cantilever towers, also known as cantilever uprights, are steel columns, pre-punched to accommodate cantilever arms at multiple storage heights. Cantilever bases are bolted or welded to the towers based on load requirements. Base units extend slightly beyond or equal to the length of the cantilever arms to prevent tipping.

5.Cantilever arms are the heart of the rack system. Choosing the proper arm capacity, arm length and arm style are essential to a successful cantilever racking system. Brace sets are bolted between pairs of towers to stabilize the rack. X-bracing increases side-to-side stability of taller towers and heavier loads.

3.Available in single and double-sided configurations, cantilever rack is made of four basic components: towers, bases, arms and brace sets.

4.Cantilever towers, also known as cantilever uprights, are steel columns, pre-punched to accommodate cantilever arms at multiple storage heights. Cantilever bases are bolted or welded to the towers based on load requirements. Base units extend slightly beyond or equal to the length of the cantilever arms to prevent tipping.

5.Cantilever arms are the heart of the rack system. Choosing the proper arm capacity, arm length and arm style are essential to a successful cantilever racking system. Brace sets are bolted between pairs of towers to stabilize the rack. X-bracing increases side-to-side stability of taller towers and heavier loads.

According to your requires,we'll design racks for you!

.jpg)