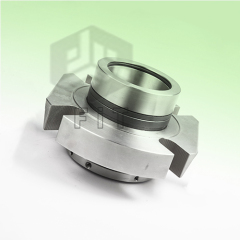

Burgmann Cartex cartridge seal

| Min. Order: | 2 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service |

| Main Products: | Cartridge Mechanical Seal, Elastomer Bellow Mechanical Seal, Grundfos Pump Seal |

Product Detail

| Model No.: | ISP-BCARTEX |

|---|---|

| Means of Transport: | Air |

| Standard or Nonstandard: | Standard |

| Style: | Mechanical Seal |

| Material: | Metal |

| Brand Name: | ISP |

| Production Capacity: | 100 sets per month |

| Packing: | In carton |

| Delivery Date: | 30 days |

Product Description

Features

Dual seal

Available for standard (Cartex-ASDN) and big bore (Cartex-ABDN) seal chambers

Cartridge

Balanced

Independent of direction of rotation

Double pressure balanced

Integrated pumping device

Advantages

Ideal for use in ANSI process pumps

Universal applicable for packings conversions, retrofits or OEM

Ideal seal for standardizations

No dimensional modification of the seal chamber necessary, small radial installation height

No damage of the shaft by dynamically loaded O-Ring

Extended service life

Installation faults are avoided, cost-effective

No damage caused by dirt entered during assembly

Straightforward and easy installation due to pre-assembled unit (reduced down-times)

Recommended applications

Water and waste water technology

Chemical industry

Petrochemical industry

Pharmaceutical industry

Food and beverage industry

Universally applicable

ANSI process pumps

Available for standard (Cartex-ASDN) and big bore (Cartex-ABDN) seal chambers

Cartridge

Balanced

Independent of direction of rotation

Double pressure balanced

Integrated pumping device

Advantages

Ideal for use in ANSI process pumps

Universal applicable for packings conversions, retrofits or OEM

Ideal seal for standardizations

No dimensional modification of the seal chamber necessary, small radial installation height

No damage of the shaft by dynamically loaded O-Ring

Extended service life

Installation faults are avoided, cost-effective

No damage caused by dirt entered during assembly

Straightforward and easy installation due to pre-assembled unit (reduced down-times)

Recommended applications

Water and waste water technology

Chemical industry

Petrochemical industry

Pharmaceutical industry

Food and beverage industry

Universally applicable

ANSI process pumps

Operating range

Shaft diameter: d1 = 25 ... 100 mm (1.000" ... 4.000")

Other sizes on request

Temperature: t= -40 °C ... 220 °C (-40 °F ... 428 °F)

(Check O-Ring resistance)

Sliding face material combination BQ1

Pressure: p1 = 25 bar (363 PSI)

Sliding velocity: vg = 16 m/s (52 ft/s)

Pressure: p1 = 25 bar (363 PSI)

Sliding velocity: vg = 16 m/s (52 ft/s)

Sliding face material combination Q1Q1 or U2Q1

Pressure: p1 = 20 bar (290 PSI)

Sliding velocity: vg = 10 m/s (33 ft/s)

Barrier fluid circulation system:

p3max = 25 bar (363 PSI)

Δp (p3 - p1)ideal = 2 ... 3 bar (29 ... 44 PSI),

7 bar (102 PSI) for barrier media with poor lubricating properties)

.jpg)