Diamond Micron Powder

| Payment Terms: | L/C, T/T, WU |

|---|---|

| Place of Origin: | Henan |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | SCMD Series |

|---|---|

| Means of Transport: | Air |

| Brand Name: | SCMD |

| Material: | Diamond |

| Packing: | Plastic or as requirments |

Product Description

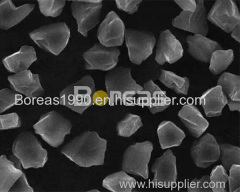

SCMD-AA

Characteristics: Selecting high intensity MBD diamond powder as the raw materials, which inherit lots of outstanding features, such as less internal impurities, low impurity, narrow distribution, high removal and grinding rates.

Application field: grinding and polishing of optical objects, sapphire and gem processing.

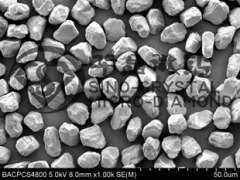

SCMD-A

Characteristics: Selecting SCD diamond powder as the raw materials, regular crystal shape, outstanding in dispersibility and purity.

Application field: Processing metal/ceramic bonded abrasive tools and electroplating work pieces.

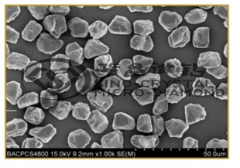

SCMD-B

Characteristics: Selecting SCD diamond powder as the raw materials, relative regular crystal shape, low impurity and narrow distribution.

Application field: Processing resin bond abrasive tools, grinding and polishing of paste, slurry and electroplating work pieces.

SCMD-C

Characteristics: Selecting RVD diamond powder as the raw materials, good shape and purity.

Application field: Processing resin bond abrasive tools and electroplating work pieces.

SCMD-PD

Description: an explosion-synthesized micron diamond powder with narrow range of sizes, high purity, more effective grinding, Actual size if from 0.1 to 10 microns.

Application field: Processing in IT industry, finishing ruby and sapphire, Ra less than 1nm. Processing fine ceramics and optical objects.