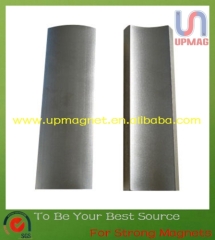

N38SH segment permanet Sintered NdFeB magnet

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 100,000pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Long Block Permanet Sintered NdFeB Magnets, Industrial Sintered NdFeB Magnet, Industrial Block Permanet Sintered NdFeB Magnet, Industrial Cylinder Permanet Sintered NdFeB Magnet, Thin Block Permanet Sintered NdFeB Magnets |

Product Detail

| Model No.: | UPS-002 |

|---|---|

| Application: | Industrial Magnet |

| Shape: | Others |

| Type: | Permanent |

| Composite: | NdFeB Magnet |

| Brand Name: | UPMAG |

| shape: | segment |

| Production Capacity: | 100,000pcs/month |

| Packing: | standard sea or air packages |

| Delivery Date: | 10-30days |

Product Description

Acr Magnets is one popular shape of Rare earth magnets and perment magnets.

It is always manufactured via Wire-Cutting,Slicing,Drilling, and grinding etc .Arc magnets have the following important factors such as ,Outer Diameter,Inner Diameter,Thickness etc

Material Grade of NdFeB magnets:

Magnet N-( N35, N38, N40, N42, N45, N48, N50,N52),

Magnet M-(35M, 38M, 40M, 42M, 45M, 48M),

Magnet H-(35H, 38H, 40H, 42H, 45H),

Magnet SH-(30SH, 33SH, 35SH, 38SH, 40SH, 42SH,45SH),

Magnet UH-( 28UH, 30UH, 33UH, 35UH, 38UH),

Magnet EH-(28EH, 30EH, 30EH, 33EH, 35EH)

1) Application of NdFeB magnet: Toys, package, Printer, Switchboard, Phone, voice coil motors (VCM's) in hard disk drives, high performance motors, brushless DC motors, magnetic separation, magnetic resonance imaging, sensors, loudspeakers etc.

2) The coating of NdFeB magnets can be Zn, Ni, Ni-Cu-Ni, Epoxy, CR3+ZN, NI+AG, NI+AU.

3) Our factory can also manufacture various sizes of NdFeB magnet, according to the customer's specification

segment permanet Sintered NdFeB magnet

| Available Coating Of Sintered NdFeB Magnets | ||||||

| Surface | Coating | Thickness(Microns)of coating | Color | Resistance | Salt spray Test Standard (hours) | Pressure Coating Test Standard (hours) |

| Passivation | 1--2μm | Silver Grey | Temporary Protection | Not available | Not available | |

| Nickel | Ni+Ni | 10--20μm | Bright Silver | Excellent against Humidity | 24 | 24 |

| Ni+Cu+Ni | ||||||

| Zinc | ZN | 3--8μm | Bright Blue | Good Against Salt Spray | 24 | Not available |

| C-Zn | shining Color | Excellent Against Salt Spray | 48 | Not available | ||

| CR3+Zinc | ZN | 3--8μm | Bright Blue | Good Against Salt Spray | 24 | Not available |

| C-Zn | shining Color | Excellent Against Salt Spray | 48 | Not available | ||

| Tin | Ni+Cu+Sn | 10--25μm | Silver | Superior Against Humidity | 48 | Not available |

| Gold | Ni+Cu+Au | 2--10μm | Gold | Superior Against Humidity | Not available | Not available |

| Ag | Ni+Ag | 2--10μm | Silver | Superior Against Humidity | Not available | Not available |

| Epoxy | Epoxy | 10--25μm | Black,Grey | Excellent Against Humidity & Salt Spray | 48 | Not available |

| Ni+Cu+Epoxy | Not available | |||||

| Zn+Epoxy | Not available | |||||

Manufacturing Process:

Different Magnetizing Direction For Choice: