Cylinder Sintered Neodymium-Iron-Boron magnet

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 100,000pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Long Block Permanet Sintered NdFeB Magnets, Industrial Sintered NdFeB Magnet, Industrial Block Permanet Sintered NdFeB Magnet, Industrial Cylinder Permanet Sintered NdFeB Magnet, Thin Block Permanet Sintered NdFeB Magnets |

Product Detail

| Model No.: | UPC-003 |

|---|---|

| Means of Transport: | Ocean |

| Application: | Industrial Magnet |

| Shape: | Bar |

| Type: | Permanent |

| Composite: | Neodymium Magnet |

| Brand Name: | UPMAG |

| material: | NdFeB |

| Production Capacity: | 100,000pcs/month |

| Packing: | standard sea or air packages |

| Delivery Date: | 10-20days |

Product Description

cylinder magnets with small diameter, tolerance can reach +/-0.03mm.

72hours for salt spray test as standard. N45 magnets have good consistency and good surface gauss.

1. Materials: Sintered Neodymium-Iron-Boron;

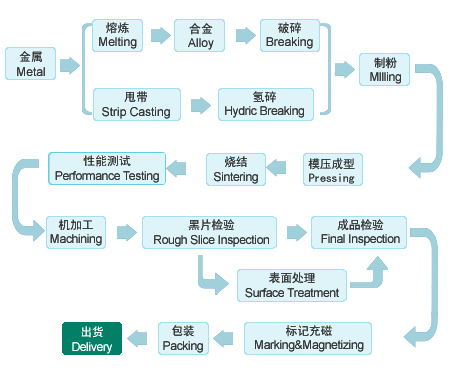

2. Technology: Utilizes new Sintered NdFeB magnet techniques and equipment such as strip casting, HDDR technology;

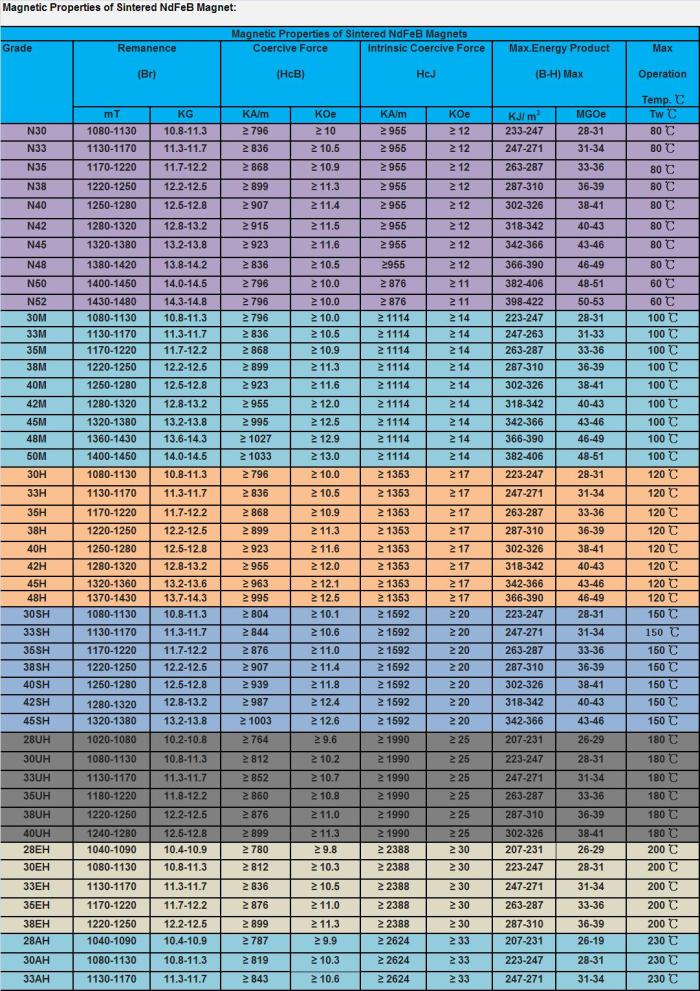

3. Magnetic properties: High coercive force, the max operation temp is up to 200 degree centigrade or 380 curie temperature;

4. Grades: N33-N52,33M-48M,33H-48H,30SH-45SH,30UH-38UH and 30EH-35EH;

5. Shapes and sizes: Various kinds or according to customers' request;

6. Coatings: Ni, Zn, gold, copper, epoxy, chemical, parylene and so on;

7. Applications: Widely used in different applications, such as sensors, motors, rotors, wind turbines/wind generators, loudspeakers, magnetic hooks, magnetic holder, filters

We are China sensors neodymium magnets manufacturer offer best sensors neodymium magnets OEM, ODM,service, at the moment, the output for the cylinder magnets is over 500,000pcs per month.

Cylinder permanet Sintered NdFeB magnet

| Available Coating Of Sintered NdFeB Magnets | ||||||

| Surface | Coating | Thickness(Microns)of coating | Color | Resistance | Salt spray Test Standard (hours) | Pressure Coating Test Standard (hours) |

| Passivation | 1--2μm | Silver Grey | Temporary Protection | Not available | Not available | |

| Nickel | Ni+Ni | 10--20μm | Bright Silver | Excellent against Humidity | 24 | 24 |

| Ni+Cu+Ni | ||||||

| Zinc | ZN | 3--8μm | Bright Blue | Good Against Salt Spray | 24 | Not available |

| C-Zn | shining Color | Excellent Against Salt Spray | 48 | Not available | ||

| CR3+Zinc | ZN | 3--8μm | Bright Blue | Good Against Salt Spray | 24 | Not available |

| C-Zn | shining Color | Excellent Against Salt Spray | 48 | Not available | ||

| Tin | Ni+Cu+Sn | 10--25μm | Silver | Superior Against Humidity | 48 | Not available |

| Gold | Ni+Cu+Au | 2--10μm | Gold | Superior Against Humidity | Not available | Not available |

| Ag | Ni+Ag | 2--10μm | Silver | Superior Against Humidity | Not available | Not available |

| Epoxy | Epoxy | 10--25μm | Black,Grey | Excellent Against Humidity & Salt Spray | 48 | Not available |

| Ni+Cu+Epoxy | Not available | |||||

| Zn+Epoxy | Not available | |||||

Manufacturing Process:

Manuacturing Equipments:

Property of magnets for choice:

.jpg)