Cylinder Block permanent Sintered neodymium Rare Earth magnet

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 100,000pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Long Block Permanet Sintered NdFeB Magnets, Industrial Sintered NdFeB Magnet, Industrial Block Permanet Sintered NdFeB Magnet, Industrial Cylinder Permanet Sintered NdFeB Magnet, Thin Block Permanet Sintered NdFeB Magnets |

Product Detail

| Model No.: | UPB007 |

|---|---|

| Means of Transport: | Ocean |

| Application: | Jewelry Magnet |

| Shape: | Block |

| Type: | Permanent |

| Composite: | Rare Earth Magnet |

| Brand Name: | UPMAG |

| material: | NdFeB |

| Production Capacity: | 100,000pcs/month |

| Packing: | standard sea or air packages |

| Delivery Date: | 10-20days |

Product Description

NdFeb magnet of various specifications and shape , such as disc or cylinder, ring and block.

ndfeb magnetic material,ndfeb

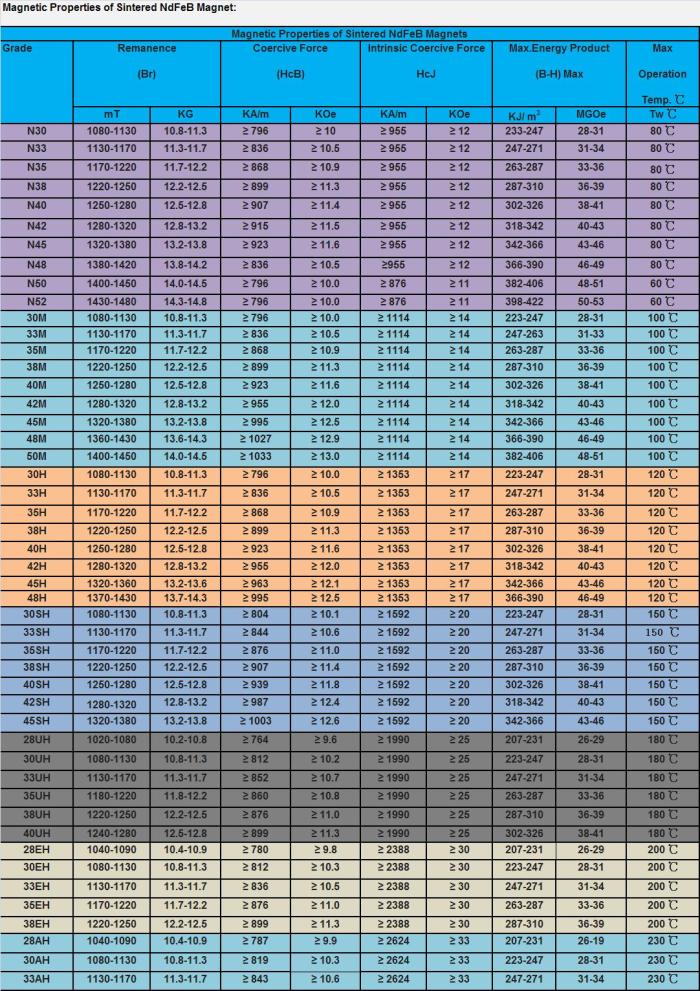

At present time, Sintered NdFeB is one of the strongest magnet materials available. It contributes to the development of many small and flat motors used in the high-tech industry. Its high residual induction (Br), high intrinsic Coercive force (Hcj) and high Energy Product (BH), makes it suitable for servo motors, disk brushless motors, stepping motors, IT industry, MRI, and audio products. For NdFeB,its surface is usually treatd with some special methods.The surface treatment method include Zine,Nickel,Tin,Silver,Gold plating,Phosphor and Spray Epoxy Resin etc

We are China industrial Block permanet Sintered NdFeB magnets manufacturer offer best industrial Block permanet Sintered NdFeB magnets OEM, ODM,service. Block permanet Sintered NdFeB magnet

Block permanet Sintered NdFeB magnet

| Available Coating Of Sintered NdFeB Magnets | ||||||

| Surface | Coating | Thickness(Microns)of coating | Color | Resistance | Salt spray Test Standard (hours) | Pressure Coating Test Standard (hours) |

| Passivation | 1--2μm | Silver Grey | Temporary Protection | Not available | Not available | |

| Nickel | Ni+Ni | 10--20μm | Bright Silver | Excellent against Humidity | 24 | 24 |

| Ni+Cu+Ni | ||||||

| Zinc | ZN | 3--8μm | Bright Blue | Good Against Salt Spray | 24 | Not available |

| C-Zn | shining Color | Excellent Against Salt Spray | 48 | Not available | ||

| CR3+Zinc | ZN | 3--8μm | Bright Blue | Good Against Salt Spray | 24 | Not available |

| C-Zn | shining Color | Excellent Against Salt Spray | 48 | Not available | ||

| Tin | Ni+Cu+Sn | 10--25μm | Silver | Superior Against Humidity | 48 | Not available |

| Gold | Ni+Cu+Au | 2--10μm | Gold | Superior Against Humidity | Not available | Not available |

| Ag | Ni+Ag | 2--10μm | Silver | Superior Against Humidity | Not available | Not available |

| Epoxy | Epoxy | 10--25μm | Black,Grey | Excellent Against Humidity & Salt Spray | 48 | Not available |

| Ni+Cu+Epoxy | Not available | |||||

| Zn+Epoxy | Not available | |||||

The property of magnets for choice:

Manufacturing Equipment: