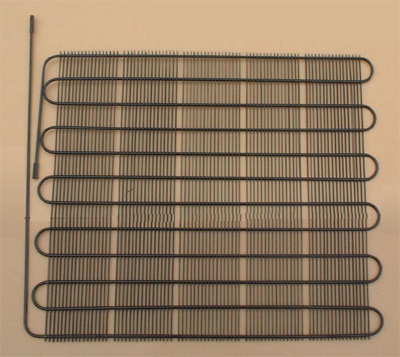

Refrigerator Condenser

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Place of Origin: | Fujian |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean |

|---|

Product Description

Wire on tube condenser

Introduction of Condenser:

The wire on tube condenser adopts the high quality Bundy Pipe and steel tube via professional import welder welding, heat exchange rate is high, Excellent thermal performance, environmental appearance, low cost, etc. Suitable for all kinds of refrigerators, freezers, show machine, water machine, etc.

The wire on tube condenser adopts the high quality Bundy Pipe and steel tube via professional import welder welding, heat exchange rate is high, Excellent thermal performance, environmental appearance, low cost, etc. Suitable for all kinds of refrigerators, freezers, show machine, water machine, etc.

Specifications:

Raw material: Rolling welded steel tube: 4.76~6.35× 0.71

Low carbon steel wire O. D1.4 ~ 1.6mm

Bracket: Steel plate(SPCC) thickness 0.6 ~ 2.0

Steel plate: SPCC thickness 0.6 ~ 0.8

Raw material: Rolling welded steel tube: 4.76~6.35× 0.71

Low carbon steel wire O. D1.4 ~ 1.6mm

Bracket: Steel plate(SPCC) thickness 0.6 ~ 2.0

Steel plate: SPCC thickness 0.6 ~ 0.8

Structure: Flat type of wire on tube condenser used at the back

Bended or spiral type of wire on tube condenser used at the bottom

Wrapped type of tube embed on plate

Bended or spiral type of wire on tube condenser used at the bottom

Wrapped type of tube embed on plate

Key process: Tube Bending, Welding, Fix the bracket, Weld the suction tube, Leakage test, Cleaning, Coating, (Folding or bending to shape), Inspection, Packing

Technical standards: Wire pitch ≥ 5

Can produce according to the drawing or sample supplied by clients, also can help the clients design and produce different condensers.

Can produce according to the drawing or sample supplied by clients, also can help the clients design and produce different condensers.

Performance: Surface with electrophoresis coating to prevent the corrosion Inner cleanness can meet the requirement of R134A & CFC cooling system Can satisfy the cooling capability requirements

Capacity: 2.5 million sets per year (8000 sets per day)

.gif)