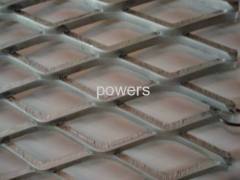

low carbon steel expanded metal sheet

16.0~22.0 USD

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 3000 |

| Place of Origin: | Hebei |

Company Profile

| Location: | Shijiazhuang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association |

| Main Products: | Hot-dip Galvanized Before Weaving Square Wire Mesh, Electro Galvanized Square Wire Mesh, Stainless Steel Plain Dutch Weave Wire Mesh, Stainless Steel Crimped Wire Meshes, Barbeque Grill Wire Mesh |

Product Detail

| Model No.: | Honbak-109 |

|---|---|

| Means of Transport: | Ocean, DHL, EMS, Air, UPS or Fedex, Land |

| Application: | Others |

| Type: | Woven |

| Material: | Others |

| Brand Name: | HONBAK |

| Mesh Size: | as customer's requirement |

| Stainless steel expanded metal mesh / Aluminum expanded metal mesh/low carbon steel wire: | Application: Protecting Mesh,Application in civil construction, machines, |

| Production Capacity: | 3000 |

| Packing: | PALLET |

| Delivery Date: | 30 DAYS |

Product Description

expanded metal sheet

A major advantage of expanded metal sheet is that the mesh is formed from a single piece of material so the processis not wasteful and therefore cost effective. The material is cut andstretched while still leaving it attached at the knuckle. This allows itto retain its shape when cut and cannot separate or fray. Often cuttingto shape is the only fabrication needed. It has excellent corrosionresistance when suitably coated, and the uncut knuckles support weightand withstand stress better than jointed welds or woven materials.

Expanded metal sheet can be supplied in a varietyof finishes, thickness, raised or flattened. Flattened is smoother anddoes not indent soft materials if this is a consideration but is not asstrong as the more robust raised mesh. Powder coating in your choice ofcolour will enhance its aesthetic appearance and add to its corrosionresistance as would plastic coating.

A major advantage of expanded metal sheet is that the mesh is formed from a single piece of material so the processis not wasteful and therefore cost effective. The material is cut andstretched while still leaving it attached at the knuckle. This allows itto retain its shape when cut and cannot separate or fray. Often cuttingto shape is the only fabrication needed. It has excellent corrosionresistance when suitably coated, and the uncut knuckles support weightand withstand stress better than jointed welds or woven materials.

Expanded metal sheet can be supplied in a varietyof finishes, thickness, raised or flattened. Flattened is smoother anddoes not indent soft materials if this is a consideration but is not asstrong as the more robust raised mesh. Powder coating in your choice ofcolour will enhance its aesthetic appearance and add to its corrosionresistance as would plastic coating.

Technical terms:

SWD: 2.5mm-50mm (Short Way of the Diamond), the distance from themiddle of the bond on one side to the middle of the bond on theopposite side.

LWD: 3mm-100mm(Long Way of the Diamond) is the distance across thelargest dimension of the diamond measured halfway between the diamonds.

Width: 0.5m-2.7m, Length:1m-3.6m

Thickness(gauge): Up to 8mm, Original thickness of metal before expanding.

Strand Width: 0.3mm to 8mm, Amount of metal between diamonds to produce one strand.

SWD, LWD Direction: Parallel to Length or Parallel to Width

LWD: 3mm-100mm(Long Way of the Diamond) is the distance across thelargest dimension of the diamond measured halfway between the diamonds.

Width: 0.5m-2.7m, Length:1m-3.6m

Thickness(gauge): Up to 8mm, Original thickness of metal before expanding.

Strand Width: 0.3mm to 8mm, Amount of metal between diamonds to produce one strand.

SWD, LWD Direction: Parallel to Length or Parallel to Width

.jpg)