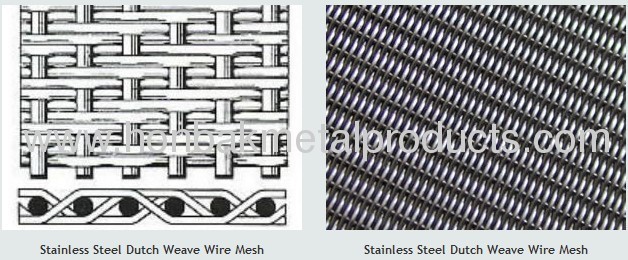

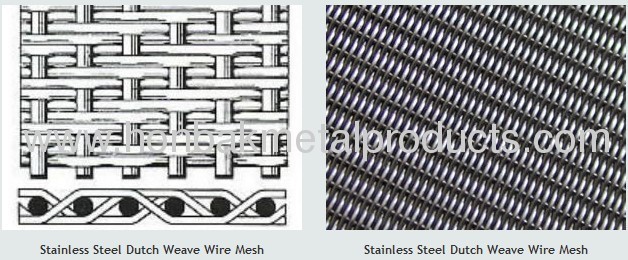

Stainless Steel Dutch Weave Wire Mesh

10.0~300.0 USD

| Min. Order: | 1 Roll |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 3000rolls/week |

| Place of Origin: | Hebei |

Company Profile

| Location: | Shijiazhuang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association |

| Main Products: | Hot-dip Galvanized Before Weaving Square Wire Mesh, Electro Galvanized Square Wire Mesh, Stainless Steel Plain Dutch Weave Wire Mesh, Stainless Steel Crimped Wire Meshes, Barbeque Grill Wire Mesh |

Product Detail

| Model No.: | Honbak13-031 |

|---|---|

| Means of Transport: | Ocean, Air |

| Production Capacity: | 3000rolls/week |

| Packing: | pallet |

| Delivery Date: | 7-15days |

Product Description

Based on weaving method , Dutch weave wire mesh can be divided into three kinds: Plain Dutch weave wire mesh,Twill Dutch wire mesh ,Reverse Dutch weave mesh. They have sdvantage in mesh thickness, filtration ratio, and lifetime due to big difference of wire dia. and mesh density in warp and weft direction, square mesh can not make it.

Honbak Dutch weave mesh with more perfect flat mesh surface, specially used in bigger leaf filter in oilrefinery industries with technical improvement of the machine, raw material choosing in high quality.

Reverse Dutch weave mesh has its own features. Example, the warp mesh count is obvious bigger than weft mesh count, and warp wire diameter smaller than weft wire diameter. It is more difficult to weave with high strength, which has instead combination of multiple layer of square mesh and common Dutch weave mesh.

Honbak mid-heavy weaving machines are good at Dutch weave mesh weaving, the products are well supplied in markets.

Dutch weave mesh widely used in folling industries, precise pressure filter, fuel oil filter, vaccum filter, astronauts, petroleum, chemical, chemical fiber, rubber, metallurgy, pharmacology, food, etc.

.jpg)

.jpg)

.jpg)