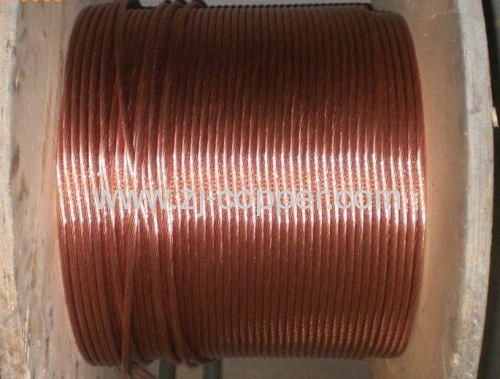

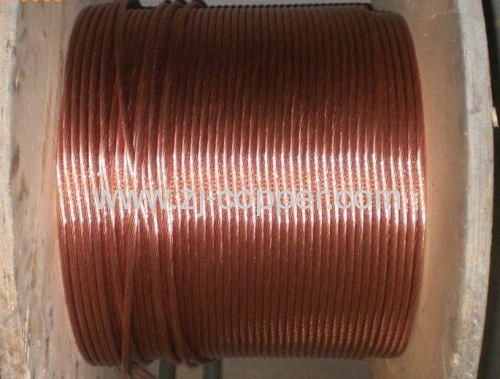

0.3mm copper clad steel strand wires

| Min. Order: | 300 Kilogram |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 900 tons monthly |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Copper Foils, Trunk Cable ; Coaxial Cable, Leaky Feeder Cbale, RG Cable, RF Coaxial Cable |

Product Detail

| Model No.: | ZJ-11-10 |

|---|---|

| Means of Transport: | Ocean |

| Production Capacity: | 900 tons monthly |

| Packing: | steel reel |

| Delivery Date: | 15 days |

Product Description

Inside with plastic film, outside weaving bag or Inside with plastic film, outside hessian cloth

Electro Galvanized Iron Wire Processing :

Galvanizedwire and all other wire mesh are manufactured by wire rod. The typeof wire rod is Q195, element composition is as follows:C≤0.07; S≤0.023;Si≤0.09; Mn≤0.32; P≤0.025.Because This type of wire rod has lessImpurities, Q195 is fit for drawing. The diameter is 6.5mm. Generally,Daily output is 120 tons.(electro and hot-dipped areseparately 60 tons)

Electro zinc coating

Packing:

Inside with plastic film, outside weaving bag or Inside with plastic film, outside hessian cloth

0.3mmcopper clad steel strand wires

Basic Information:

Basic Information:

1. Material :is Q195.

2. Wire Diameter : 0.2mm~4.5mm

3. Zinc Coating : 10g/m2 ~ 15g/m2

4.Tensile Strength: 300N~700N

1 Use of galvanized wire :

1 Use of galvanized wire :

Galvanized barbed wire is mainly used in construction as binding wire, express way

fencing as fencing wire, binding of flowers as wire ties in the garden and yard, and

wire mesh making as weaving wires. Electro Galvanized Iron Wire Processing :

Galvanizedwire and all other wire mesh are manufactured by wire rod. The typeof wire rod is Q195, element composition is as follows:C≤0.07; S≤0.023;Si≤0.09; Mn≤0.32; P≤0.025.Because This type of wire rod has lessImpurities, Q195 is fit for drawing. The diameter is 6.5mm. Generally,Daily output is 120 tons.(electro and hot-dipped areseparately 60 tons)

Drawing

Galvanized wire's first stage is drawing.

thereare two kinds of drawing machine: powder drawing and water drawing.powder drawing is fit for junior drawing(6.5mm~4.0mm). One powderdrawing machine has 4 tanks and 4 molds. One tank is matched with amold. Each of them are offered energy by a electromotor. 0.9mm(max)canbe "eat" when the wire cross a mold. There are no loss of weight duringdrawing.

Annealing

Afterdrawing, the wire is thinner, but also very hard. The tensile strengthis about 700N. These wire can be used to produce nail and mesh panel.For galvanized wire, it still need annealing

Annealing

Galvanized wire's second stage is anneal.

Annealis to low the tensile strength of wire. The stove is solid and builtwith red bricks. The architecture of anneal stove is cuboid. Different thickness of wire require different temperature. Range is from 700°C to900°C. Output of the anneal stove, the tensile strength is 400N~600N.

Electro zinc coating

Galvanized wire's fourth stage: Zinc coating

Afterthe chlorhydric acid pool, water pool is also necessary. In the zincpool, displacement reaction is chemical and uniformly distributed. Thesurface of wire is smooth. Because wire cross the zinc pool fast,abundant zinc coating requires 4 zinc pools

Packing:

Inside with plastic film, outside weaving bag or Inside with plastic film, outside hessian cloth