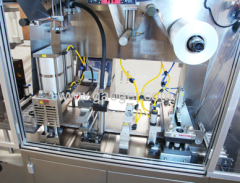

Capsule Blister packing and Cartoning Packaging Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 10sets per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Wenzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | ZHB-100 Full Automatic Cartoning Machine, Tube Automatic Cartoning Machine, Injection Automatic Cartoning Machine, Full Automatic Cartoning Machine, Pre-filled Syringe Blister Packing And Cartoning Packaging Line |

Product Detail

| Model No.: | DHC-350Z |

|---|---|

| Means of Transport: | Ocean |

| Model: DHC-350Z: | Brand: Gaoger |

| Processing: Caspule packing machine,Tablet packing line: | Automatic Grade: Automatic |

| Place of origin: China: | Company type:Manufacturer |

| Production Capacity: | 10sets per month |

| Packing: | Sea worth wooden Case |

| Delivery Date: | 100days |

Product Description

DHC-250Z Medical Blister Packing and Cartoning Packaging Line

pharmaceutical packaging line

Capsule Blister Packing and Cartoning machine

Tablet Blister Packing and Cartoning Machine

1.Blister Packing machine

2.Blister packing for medicine,capsule,tablets

3.Automatic

4.With CE and cGMP

Applications:

The packaging line can be widely used for packing different size of capsule ,tablet and solid products(Alu-PVC/Alu-Alu) blister packing and cartoning. Can be connected with weighing machine, strapping machine, carton packer and other equipment ,thus formed a complete automatic packaging production line

Feature:

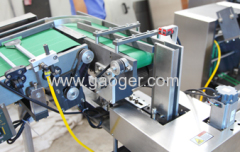

1.Machine with GMP and cGMP standard,adopts PLC control system ,servo motor drive control.

2.All components that contact with medical are made of high anti-corrosive SS316.

3.Equipped Camera detection, lack of material testing, to ensure the passing rate of finished products

4.Uses the safety cover protection devices to ensure operator safety.

5. Machine can be separated to some parts,order easy move into the elevator and clean room

6. Optional : Aluminum foil online printing system(HAPA Aluminum foil printer)

Main data:

| Maximum blanking frequency | Alu/ PVC: 50 time/min AL/AL 30time/min |

| Maximum working capacity | Alu/ PVC: 200 blisters/min AL/AL :120 blisters/min |

| Stroke | 130mm (according to customer's request) |

| Maximum forming area | 245x122mm |

| Maximum forming depth | 18mm (upon request) |

| Packaging material | PVC: 260x0.25(0.15-0.5)mm |

| PTP: 260x0.02mm | |

| Power supply | Four wire three phrase 380V 50Hz (220V 60Hz) |

| Total power | 5.7KW |

| Power of main motor | 1.5KW |

| Air flow | 0.38m3/min |

| Dimension of machine(L*W*H) | 4200x650x1700mm |

| Weight | 1500kg |

.jpg)