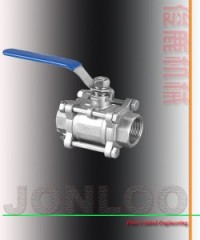

stainless steel ball valve

have very compact design. Only a quarter turn operation is required to close the valve from fully open condition and vice-versa. The inside ball moves on the Teflon Seals, at the adaptor face and stem faces contact with the Teflon rings. there is no torque in the operation of Valve for long time. - Design: one piece and three piece

- Type: Two way, Three way, Four way & Line mounting

- Size Range: 1/4" to 2" NB in Screwed end, 1/2" to 4" NB in flanged end

- End Connection: NPT / BSP/ SW/BW and Flanged as per BS -10, ASA and DIN Standards.

- Material: SS316/ SS 304 / CS / Brass with SS working parts

- Pressure Rating: 300 psig to 5000 psig.

FEATURES:- Panel mountings are available as an option.

- Internally loaded stem with shoulder to prevent stem blowout.

- Low operating torque.

- Floating ball desing ensures leak proof shut-off at hight pressure.

- Maximum orifice to minimize the pressure drop.

- Rugged body construction and floating ball is machined from base stock.

- Handle with arrow indicates flow indicates flow direction allows quick operation and low torque with 1/4 turn.

- Encapsulating ball seats are uniformly forced to form tight seals against ball and body cavity and virtually allow no dead volume. Interal ball-stem is machined form one single piece and best suited to encapsulating ball seals.

| |

.jpg)

.jpg)