Permanent Magnetic Chuck from AMT&C

100.0~500.0 USD

| Min. Order: | 5 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 1000sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Cup Magnets, Coating NdFeB Magnets, Ceramic Magnet, Cylinder NdFeB Magnet Neodymium Rare Earth Permanent Magnet, Countersunk Pot Magnet |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| The supplier of equipment: | AMT&C |

| Production Capacity: | 1000sets/month |

| Packing: | according to consumers' request |

| Delivery Date: | 15 days |

Product Description

introduction of products:

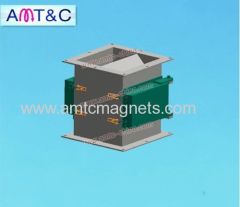

Permanent Magnetic Chuck of AMT&C

Permanent Magnetic Chuck of AMT&C

Permanent magnetic chuck were designed to hold workpieces for turning on the lathe machines and for grinding machines and milling machines. We can supply two types of permanent magnetic chuck, rectangular permanent magnetic chuck and round permanent magnetic chuck. The permanent magnetic chucks have super strong magnetic force but less remaining magnetism.They are easy for operation. Please choose a permanent magnetic chuck which you need from from the following items:

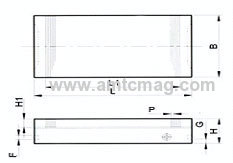

Rectangular Permanent Magnetic Chuck:

Magnetic Chuck Properties:

Standard Sizes Rectangular Permanent Magnetic Chuck

| Item Code | B Width | L Length | Effective Length | H Height | H1 Top plate height | F | G | Pole Pitch | Net Weight |

| PMCR-1018 | 100 | 175 | 145 | 52 | 20 | 10 | 10 | 1+3 | 8 |

| PMCR-1325 | 125 | 250 | 213 | 52 | 20 | 10 | 10 | 1+3 | 14 |

| PMCR-1515 | 150 | 150 | 117 | 52 | 20 | 10 | 10 | 1+3 | 9 |

| PMCR-1530 | 150 | 300 | 257 | 60 | 23 | 10 | 10 | 1+3 | 21 |

| PMCR-1535 | 150 | 350 | 305 | 60 | 23 | 10 | 10 | 1+3 | 25 |

| PMCR-1540 | 150 | 400 | 357 | 60 | 23 | 10 | 10 | 1+3 | 28 |

| PMCR-1545 | 150 | 450 | 405 | 60 | 23 | 10 | 10 | 1+3 | 32 |

| PMCR-2030 | 200 | 300 | 257 | 60 | 23 | 10 | 10 | 1+3 | 28 |

| PMCR-2035 | 200 | 350 | 305 | 60 | 23 | 10 | 10 | 1+3 | 33 |

| PMCR-2040 | 200 | 400 | 357 | 60 | 23 | 10 | 10 | 1+3 | 37 |

| PMCR-2045 | 200 | 450 | 405 | 60 | 23 | 10 | 10 | 1+3 | 43 |

| PMCR-2050 | 200 | 500 | 457 | 60 | 23 | 10 | 10 | 1+3 | 53 |

| PMCR-2063 | 200 | 630 | 585 | 60 | 23 | 10 | 10 | 1+3 | 69 |

| PMCR-2535 | 250 | 350 | 305 | 60 | 23 | 10 | 10 | 1+3 | 47 |

| PMCR-2540 | 250 | 400 | 357 | 60 | 23 | 10 | 10 | 1+3 | 53 |

| PMCR-2563 | 250 | 630 | 585 | 60 | 23 | 10 | 10 | 1+3 | 86 |

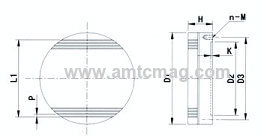

Round Permanent Magnetic Chuck

Standard Sizes for Round Permanent Magnetic Chuck

| Item Code | Diameter | Effective Length | Height | Pole Pitch | D2 | K | N | M | D3 | Net Weight |

| PMCC-150 | 150 | 117 | 50 | 1+3 | 110 | 4 | 4 | 8 | 132 | 7 |

| PMCC-160 | 160 | 129 | 50 | 1+3 | 120 | 4 | 4 | 10 | 140 | 8 |

| PMCC-200 | 200 | 169 | 52 | 1+3 | 160 | 4 | 4 | 10 | 180 | 12 |

| PMCC-250 | 250 | 213 | 52 | 1+3 | 200 | 4 | 4 | 10 | 230 | 19 |

| PMCC-300 | 300 | 265 | 54 | 1+3 | 250 | 4 | 4 | 12 | 280 | 28 |

| PMCC-400 | 400 | 365 | 58 | 1+3 | 320 | 4 | 4 | 12 | 380 | 53 |

| PMCC-600 | 600 | 553 | 62 | 1+3 | 500 | 4 | 4 | 12 | 580 | 134 |

Uses

- Tool room grinding

- Suitable for light milling EDM applications

Standard Features and Benefits

- Full magnetic surface to all edges - powerful holding over entire chuck surface

- Fine pole divisions - for more uniform magnetic holding of small parts

- Solid construction top plate - protects permanent magnetic pack from penetration of EDM fluids. Provides stronger and more rigid work surface

- Lowest height of any permanent chuck - for added clearance on larger workpieces

- Can be used inverted for holding electrode on ram

- Supplied with (2) hold down clamps

- Magnetic field does not affect EDM operation

- Special Flatness and Parallelism Tolerances available on request

- Optional Stainless Steel Construction and Flushing Holes on request