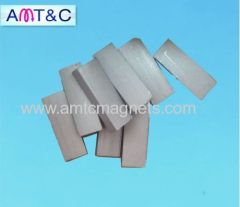

Samarium cobalt (SmCo) bread-shape magnet

1.0~5.0 USD

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 35000pcs/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Cup Magnets, Coating NdFeB Magnets, Ceramic Magnet, Cylinder NdFeB Magnet Neodymium Rare Earth Permanent Magnet, Countersunk Pot Magnet |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Application: | Industrial Magnet |

| Shape: | Strip |

| Type: | Permanent |

| Composite: | Rare Earth Magnet |

| Brand Name: | AMT&C |

| Grade: | S28G |

| bread-shape size: | 32*8.5*R36* 6.9 |

| Coating: | No |

| Magnetization direction: | Couple magnetized: 50% N (S) and 50% S (N) |

| Maximum Working Temp.: | 350℃ |

| Production Capacity: | 35000pcs/Month |

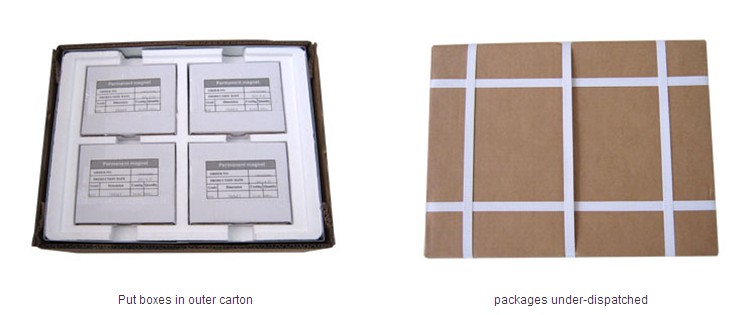

| Packing: | standard export package or according to customers' request |

| Delivery Date: | 30days |

Product Description

General Information

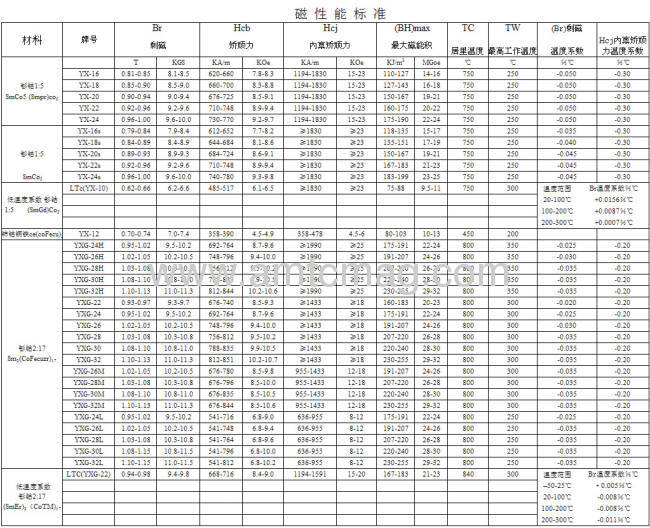

Collectively known as Rare Earth magnets, Samarium Cobalt (SmCo) and Neodymium Iron Boron (NdFeB) magnets are alloys of the Lanthanide group of elements. Rare Earth magnets are the most advanced commercialized permanent magnet materials today. SmCo magnets are available in a number of different grades that span a wide range of properties and application requirements.

SmCo magnets are brittle and machining operations should be performed prior to magnetization, using diamond tools. We are equipped to fabricate these materials to blueprint specifications.

SmCo magnets are anisotropic, and can only be magnetized in the orientation direction. In general, magnetizing fields of about 35 to 45 kOe are required to saturate SmCo materials.

SmCo2:17 magnet is also named Sm2Co17. Prorated with metallic samarium, cobalt, Copper, iron and zirconium, are firstly those roughcasts with different properties and grades after series technology processing from melting, milling, pressing to sintering in order. The (BH) max range is from 20 to 32, maximum working temperature 350°C. Sm2Co17 bears a extremely low temperature coefficient and preferably anti-causticity. In high-temperature conditions, the magnetic properties is better than NdFeB magnets, As a result, it's widely used in fields such as aeronautics and space, national defense and sensors.

Attributes

- Extremely resistant to demagnetization

- Good temperature stability (maximum use temperatures between 250 °C (523 K) and 550 °C (823 K); Curie temperatures from 700 °C (973 K) to 800 °C (1,070 K)

- Samarium - cobalt magnet has a strong resistance to corrosion and oxidation resistance, usually do not need to be coated and can be widely used in high temperature and poor working conditions.

Performance:

Packing diagram:

.jpg)