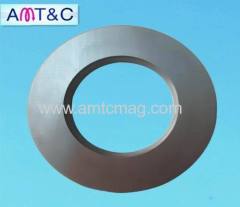

Rare Earth NdFeB Magnets Ring Industry

10.0~15.0 USD

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 500000pcs/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Cup Magnets, Coating NdFeB Magnets, Ceramic Magnet, Cylinder NdFeB Magnet Neodymium Rare Earth Permanent Magnet, Countersunk Pot Magnet |

Product Detail

| Model No.: | From N35 to N52 |

|---|---|

| Means of Transport: | Ocean, Air |

| Application: | Industrial Magnet |

| Shape: | Others |

| Type: | Permanent |

| Composite: | Neodymium Magnet |

| Brand Name: | AMT&C |

| Grade: | according to customers' request |

| Ring Size: | according to customers' request |

| Coating: | according to customers' request |

| Magnetization Direction: | UNMAGNETIZED, Texture axial |

| Maximum Working Temp:: | according to customers' request |

| Production Capacity: | 500000pcs/Month |

| Packing: | standard export package or according to customers' request |

| Delivery Date: | within 15days |

Product Description

NdFeB Ring Magnets Overview:

NdFeB (Neodymium-Iron-Boron) – is the most powerful rare-earth permanent magnet, because of this, it called super magnet or strong magnet . NdFeB magnet was developed from the year of 1983 and became commercially available in 1984. Neodymium magnet have the highest Br, and BHmax of any magnet formula, NdFeB(Neodymium-Iron-Boron) magnet is used most popular by people in industry and our daily life, because it has superior magnetic properties than other kind of magnet.

The outstanding characteristics are as follows--------

*Higher unit magnetic properties than other magnet and assure you of smaller size and lighter weight in designing devices.

*Being mostly an iron based alloy, NdFeB type rare earth magnet is much more prone to surface oxidation or rust. To eliminate such a problem, the user should consider magnet coating, plating, or suitable surface treatment.

*Being less prone to chipping during handing

*Lower temperature coefficient of magnetic properties than ceramic but higher than SmCo type rare earth magnet. Therefore, this NdFeB type rare earth magnet will suffer irreversible loss at high temperature

The Nd-Fe-B permanent magnets, which are called the next centurial magnets, are used in a wide range of industries including computer, automobile, electric machinary, electro-sound devices, automatic control, magnetic force mechanism, microwave commnication, petrochemical industry, medical apparatus and equipment. The magnets are the ideal materials for the subminiature magnetic devices with high function

NdFeB is made of Neodymium(Nd)-Iron(Fe)-Boron(B) and provides the strongest magnetic energy than any other magnet. Its energy product range is from 28 MGOe to 52 MGOe, and is widely used in apparatus and instruments where a strong magnetic field is needed such as devices for avionics, spacecraft, electronic instruments, linear motors and etc.

Advantage of Sintered NdFeB Magnet:

*Extreme strong Br Resident induction.

*Excellent demagnetization resistance capability.

*Various sizes and grades are available.

NdFeB (Neodymium-Iron-Boron) – is the most powerful rare-earth permanent magnet, because of this, it called super magnet or strong magnet . NdFeB magnet was developed from the year of 1983 and became commercially available in 1984. Neodymium magnet have the highest Br, and BHmax of any magnet formula, NdFeB(Neodymium-Iron-Boron) magnet is used most popular by people in industry and our daily life, because it has superior magnetic properties than other kind of magnet.

The outstanding characteristics are as follows--------

*Higher unit magnetic properties than other magnet and assure you of smaller size and lighter weight in designing devices.

*Being mostly an iron based alloy, NdFeB type rare earth magnet is much more prone to surface oxidation or rust. To eliminate such a problem, the user should consider magnet coating, plating, or suitable surface treatment.

*Being less prone to chipping during handing

*Lower temperature coefficient of magnetic properties than ceramic but higher than SmCo type rare earth magnet. Therefore, this NdFeB type rare earth magnet will suffer irreversible loss at high temperature

The Nd-Fe-B permanent magnets, which are called the next centurial magnets, are used in a wide range of industries including computer, automobile, electric machinary, electro-sound devices, automatic control, magnetic force mechanism, microwave commnication, petrochemical industry, medical apparatus and equipment. The magnets are the ideal materials for the subminiature magnetic devices with high function

NdFeB is made of Neodymium(Nd)-Iron(Fe)-Boron(B) and provides the strongest magnetic energy than any other magnet. Its energy product range is from 28 MGOe to 52 MGOe, and is widely used in apparatus and instruments where a strong magnetic field is needed such as devices for avionics, spacecraft, electronic instruments, linear motors and etc.

Advantage of Sintered NdFeB Magnet:

*Extreme strong Br Resident induction.

*Excellent demagnetization resistance capability.

*Various sizes and grades are available.

Material:

1.Permanent Magnet.

2.Sintered Neodymium-Iron-Boron.

NdFeB magnet is an alloy magnet made from Nd,Fe,B and other metal elements,which has the high remanence,high coercive force,high energy and high performance/cost ratio.The highest magnetic properties is from 33MGOe to 52MGOe,and we are able to control the magnetic properties within the range as you demanded,like SH,UH,EH such high stable properties could be produced as per your industrial application.

We focus on Sintered NdFeB magnet and develop it under experienced engineer and passionate&studious sales team.

Key Advantages:

1.Neodymium magnets are the most powerful commercially produced magnets.

2.Higher Maximum Energy Product ranging from 30 MGOe to 52 MGOe.

3.Neodymium magnets can replace Samarium Cobalt magnets, especially where operating temperature is lower than 176F/80C.

4.Very high strength and relatively low cost.

5.Compared to Alnico and Sm-Co magnets, relatively easier to machine.

Specification:

2.Higher Maximum Energy Product ranging from 30 MGOe to 52 MGOe.

3.Neodymium magnets can replace Samarium Cobalt magnets, especially where operating temperature is lower than 176F/80C.

4.Very high strength and relatively low cost.

5.Compared to Alnico and Sm-Co magnets, relatively easier to machine.

Specification:

1.High coercive force, strong magnetic power;

2.The maximum operation up to 200 degree centigrade or 380 curie temperature;

3.Products manufactured according to ISO9001 quality system;

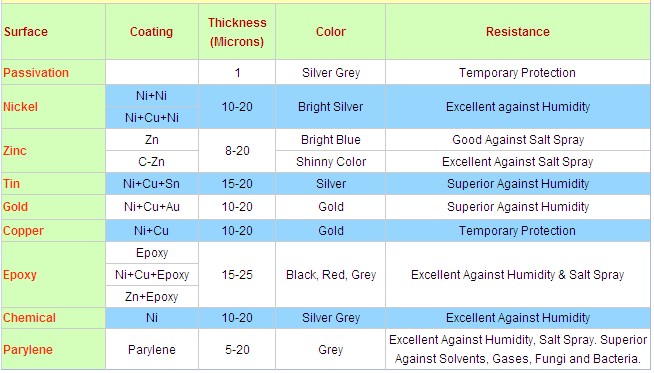

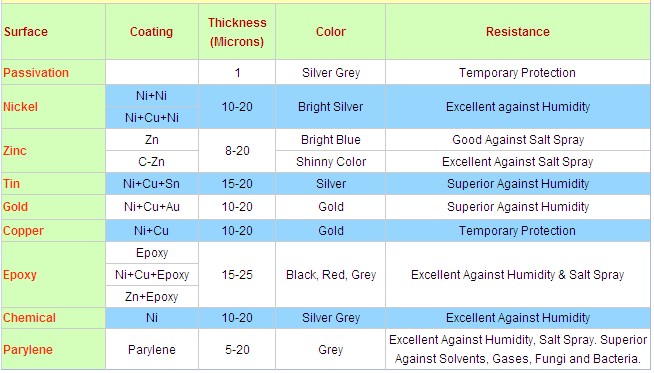

4.Coating: Ni, Ni-Cu-Ni, Zn, Ag, Au and other special plating and coating ;

5.Delivery time: According to customers 'requirement;

6.Payment terms: T/T, L/C or Western Union

7.Service:we will do our best to serve you if we have the opportunity to cooperate with you

Producing process of sintered NdFeB:

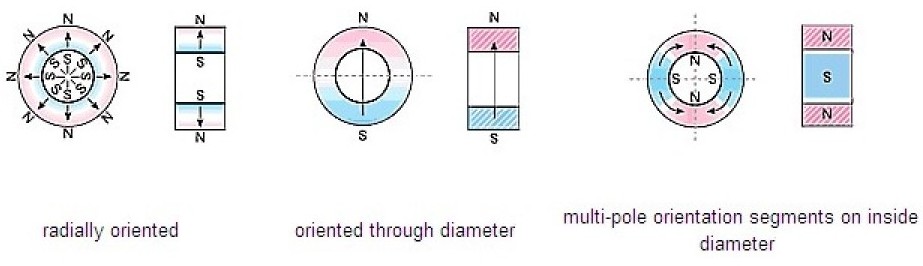

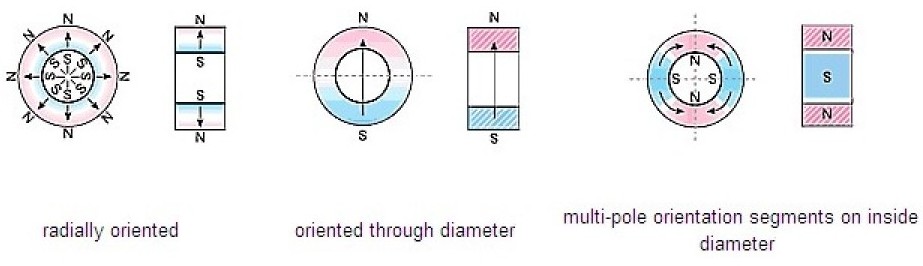

MAGNETIZED DIRECTION:

Coating:

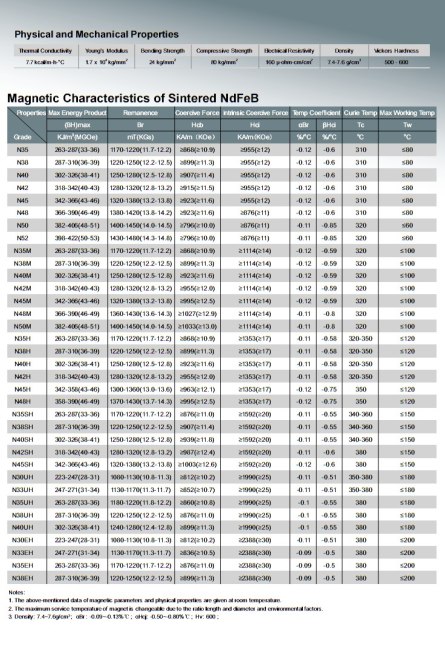

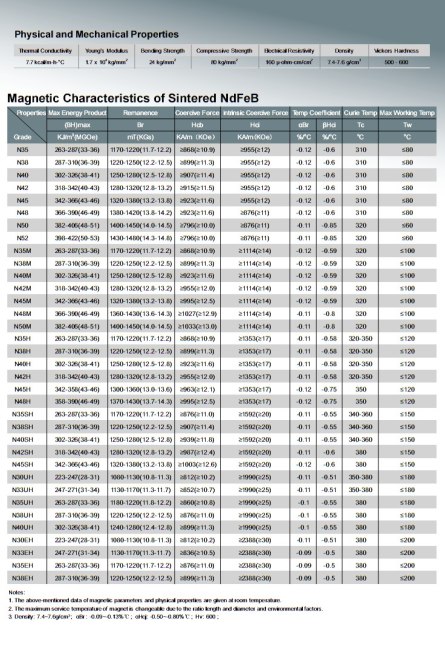

Performance:

MAGNETIZED DIRECTION:

Coating:

Performance: