Thrust ball bearing

| Place of Origin: | Zhejiang |

|---|

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | CKS Series Clutch Bearing, CSK(KK) Series Clutch Bearing, LFR Series Track Roller Bearing, LV Series Track Roller Bearing, LR Series Track Roller Bearing |

Product Description

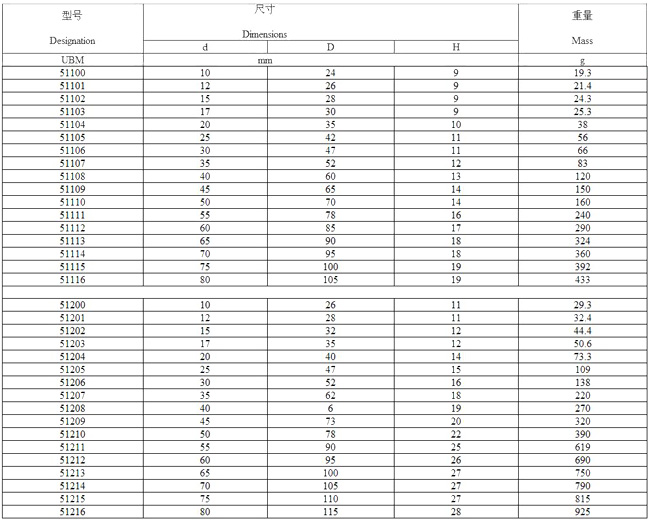

UBM - thrust bearing and its components is a unit composed of thrust cage and thrust ball with thrust

washer. It can also consist work-pieces used separately. Featuring compact structures, capability of bearing single-direction axial force, high loading ability and high rigidity. It is widely used in lathe, metallurgical and textile machinery; motor, driving shaft, gearbox and other location & supporting location.

Types of Designs:

For bearing rolling body is thrust balls.

For cages, materials of steel and non-ferrous metal can be chosen.

There are different structures of cages, such

as machined & punched.

Product Precision Accuracy:

Dimensional tolerance and geometrical

accuracy is based on GB/T307.

Matched steel ball accuracy is grade 20 (ISO

GB/T308).

Materials:

Material for rolling body is GCr15 bearing

steel, quench-hardening HRC60-65. Material for thrust washer is GCr15 bearing steel, quench-hardening HRC61-65. Material for punched parts is quality low- carbon steel.

Material for cages is nylon\low-carbon steel

or non-ferrous metal.

Special Directions:

Easy to mount, but axial preloading during

installation is to be fully considered.

.jpg)

.jpg)