SOLAR CELL

| Place of Origin: | Zhejiang |

|---|

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

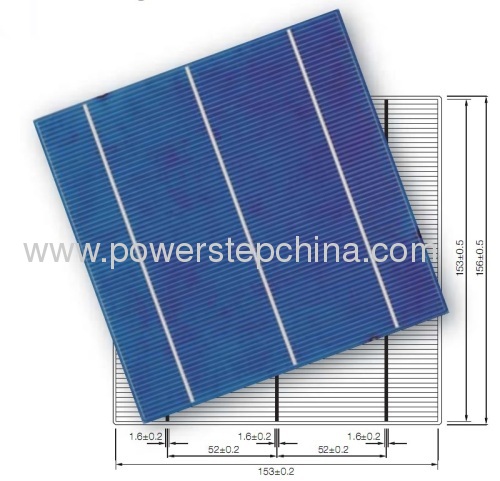

| Model No.: | Poly-crystalline solar cells 6" 156x156 |

|---|---|

| Material: | Polycrystalline Silicon |

Product Description

Imported cleaning equipment is used to keeping the appearance of the solar cell tidy and clean. And the advanced proliferation technology is adopted to ensure the conversion efficiency uniformity throughout cell; Advanced PECVD film forming technology is used to coat the cells with dark blue silicon nitride antireflection coatings with uniform color appearance; Using advanced " Softline" printing line and high precision silk screen printing equipment to achieve high smoothness of the solar cell and make the automatic welding and laser cutting of the solar cell easier; High quality metal paste is applied to making back surface field and the electrode to ensure top conductivity, good adhesion, superior weldability, nice appearance, and reliable performance. To ensure the efficiency, stability and durability of the crystal silicon!

The features of the solar cell:

□ homogeneous acid or caustic soda;

□ Enhanced Blu-ray spectral response;

□ silicon nitride antireflection coating;

□ the highest standards of the positive silver electrode;

□ silver aluminum negative electrode;

□ aluminum back surface field;

Efficiency(%) Pmp p(VV) Ummp p(V) Imp p(A) Voc(V) I sc(A) FF(%)

16.25-16.50 3.99 0.512 7.792 0.618 8.308 77.67

16.00-16.25 3.92 0.512 7.681 0.616 8.204 77.50 15.75-16.00 3.86 0.512 7.600 0.614 8.099 77.50

15.50-15.75 3.80 0.512 7.526 0.611 8.059 77.23

15.25-15.50 3.74 0.512 7.480 0.610 8.010 77.53

15.00-15.25 3.68 0.512 7.404 0.608 7.933 76.265 14.75-15.00 3.62 0.512 7.327 0.606 7.855 76.21

14.50-14.75 3.56 0.512 7.249 0.604 7.786 75.72

14.25-14.50 3.50 0.512 7.172 0.602 7.721 75.30

14.00-14.25 3.44 0.512 7.076 0.602 7.631 74.87

.jpg)

.jpg)