Scraper conveyor

| Payment Terms: | L/C |

|---|---|

| Place of Origin: | Hebei |

Company Profile

| Location: | Cangzhou, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Brand Name: | TONGMING |

| Material Feature: | Heat Resistant |

| Structure: | Roller Conveyor |

| Type: | Screw Conveyor |

Product Description

Quick Details

| Place of Origin: Hebei China (Mainland) | Brand Name: TONGMING | Material: Stainless Steel |

| Material Feature: Heat Resistant | Structure: Roller Conveyor | Type: Screw Conveyor |

| Condition: Used | Material: Steel |

Specifications

2 Light and Flexible, wear-free, low noise, long lifespan

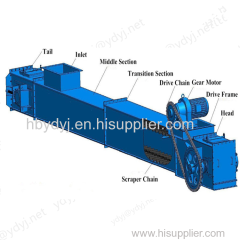

The Structure of the scraper conveyor

The scraper conveyor is composed by five parts: material container, cycle chain, scraper, mechanical power head and the tail.

1. The material container

The material container is usually enclosed; it is the material transport path.

The scraper will drive to move the material in this path, the moving distance is determined by the length of the material container, as well the material moving quantity is determined by its area of section.

2. Cycle chain

The scraper's moving course is determined by the cycle chain, all of the scrapers are fixed on the chain. So when the chain moves, the scrapers will be move by the chain's traction, and then the scraper bring the material to move.

3. Scraper

The mounting brackers are made of abrasion-proof material; the plates are installed on the mounting brackers. The chain draw the mounting brackers to move and the mounting brackers push the materials to move. This equipment is so called scraper.

4. Mechanical power head

The mechanical is a gear which transfers the motor's circular motion to the chain linear motion. This gear contains motor, speed reducer and chain wheel.

5. Tail

The tail is composed by chain wheel and rotary engine, the tail is the place where the scraper changes its motion direction.

The advantage of the former scraper conveyor

- The material can be feed enclosed, achieve civilized production.

- Light and Flexible

Disadvantage of the former scraper conveyor

- Under non-linear transport, due to the direct friction between the scraper and the material container, the equipment needs overhaul every 45 working days that costs a lot.

- The included angle ≤25°, and it can only accept one angle. Under such an condition, the operation will make great deal of noise, which will shorten the service life. Need overhaul every 280 working days with large operation expense and bad reliability.

The new type wear-free scraper conveyor

The new type scraper conveyor is reformed in the basic of the traditional scraper conveyor principles. Its advantages are as following:

- Large-angles, in one scraper conveyor path can installed several angles each of which is ≤150°

- Wear-free, in all of the conveying paths, the scrapers have no touch with the material container, so it can be called wear-free scraper conveyor.

- Long service life, because of the zero abrasion between the scrapers and the material container, the service life of the product is extended to more than 1750 working days.

- Low nose, when the scraper conveyor runs, because there is no fraction, the nose is very low.

- Energy-saying, under the same media, same conveying distance, and same conveying quantity, for wear-free, the linear convention can save 25% energy. And if the included angle is 25°, it can save 37% energy.