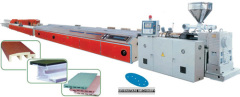

PVC wood plastic sheet extrusion line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 40-180kg/h |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Plastic Machinery, PVC Pipe Extruding Line, PP PE Pipe Production Line, Plastic Recycling And Granulating Machine, Plastic Sheet Extruder |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Production Capacity: | 40-180kg/h |

| Packing: | wood case |

| Delivery Date: | 45 working days |

Product Description

PVC wood plastic machinery can use the one step extrusion method and also it can use the two-step extrusion method after palletizing. The two-step extrusion method can save the power and space, and the two-step extrusion method features the machine can the humidity from the wood powder. So that the feeding section of the extruder can be filled with enough material and the plastification effect will be better. Special and well designed screw enables the raw material to be evenly stay in the extruder. The screws and the barrel are bi-metallic treated, more wearable and anti-corrosion.

II. Technical parameters

II. Technical parameters

| Machine Type | Length-diameter Ratio | Rotational Speed (r/min) | Total Power (KW) | Output (Kg/h) | Outline Dimension (mm) | Total Weight (Kg) |

| DM-1 | 10-32 | 30-80 | 75 | 40-60 | 13500*1050*2400 | 4900 |

| DM-2 | 10-32 | 30-60 | 103 | 70-120 | 21860*2000*3200 | 7800 |

| DM-3 | 10-32 | 30-60 | 126 | 90-180 | 22580*2200*3200 | 8900 |