Compound Insulation Heat Shrinkable Tape for emergency repair shrink tape yellow red black green 5m per roll up to 35 kV

0.09 USD

| Min. Order: | 100 Meter |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,CPT,FCA,EXW |

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 30t/month |

| Place of Origin: | Liaoning |

Company Profile

| Location: | Dalian, Liaoning, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

Product Detail

| Model No.: | T1 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Material: | Others |

| Brand Name: | UPM heat shrink |

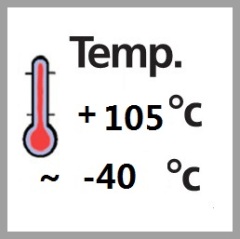

| Highest Working Temperature: | 105 ℃ |

| color: | Black, Yellow,Red,Green |

| Voltage class: | up to 36KV |

| Insulation ,sealing,protection: | flame retardant heat shrink tube |

| hot sale 2014: | thin wall heat shrink tubing |

| Tel: | 86-15940969469 |

| Contact: | Lily Zhang / Lily@upolymer.com |

| Protects aginst flashover: | Conforms to irregular shaped objects |

| Reduces bus bar clearance requirement: | ROHS compliant |

| oxgen index: 27: | dielectric constant: 2.5~3.5 |

| Width: 25mm or 50mm: | Voltage Class: 0.6~36KV |

| Production Capacity: | 30t/month |

| Packing: | standard carton packaging |

| Delivery Date: | within 3 weeks |

Product Description

| T1 Compound Insulation Heat Shrinkable Tape | ||||

| Features | ||||

| Cross-linked polyolefin outer layer | Operating temperature: -40~105℃ | |||

| Pre-coated adhesive inner layer | Shrink temperature: 125℃ | |||

| Conforms to irregular shaped objects | Voltage class: ≤ 36 KV | |||

| Protects against accidental flashover | Flame retardant | |||

| Reduces bus bar clearance requirement | RoHS compliant | |||

| Compatible with most other insulation materials | ||||

| Dimensions | ||||

| Reference | Voltage class | Tape thickness | Tape width | Standard length |

| UPM T1 | (KV) | (mm) | (mm) | m/spool |

| T1-25A | 6~15 | 0.8~1.0 | 25 | 5 |

| T1-25B | 24~36 | 1.3~1.5 | 25 | 5 |

| T1-50A | 6~15 | 0.8~1.0 | 50 | 5 |

| T1-50B | 24~36 | 1.3~1.5 | 50 | 5 |

| Typical application | ||||

| Ideal for emergency repair of electrical power system | ||||

| Suitable for insulation and protection of odd-shaped electrified objects, where tubing/sleeve | ||||

| shaped materials are not applicable | ||||

| Ordering | ||||

| Standard color : Black, Yellow, Red, Green | ||||

| Standard packaging by spools. Tape width: 25mm and 50mm are available | ||||

| Please specify specification, color, quantity when ordering | ||||

| Cross reference | ||||

| Raychem/ Tyco : HVBT | ||||

| Technical Data | ||||

| Property | Test method | Values | ||

| Physical | Tensile strength | ASTM D2671 | ≥10.4MPa | |

| Breakdown elongation | ASTM D2671 | ≥ 200% | ||

| Aging (136℃ /168hrs) | Tensile strength | ASTM D2671 | ≥8 MPa | |

| Breakdown elongation | ASTM D2671 | ≥160% | ||

| Low temperature flexibility(-40 ℃/4hrs) | ASTM D2671 | No cracking | ||

| Water absorption | ASTM D570 | ≤0.5% | ||

| Electrical | Volume resistivity | ASTM D2671 | ≥1014Ω.cm | |

| Dielectric strength | ASTM D2671 | 20~25 KV/mm | ||

| Dielectric constant | GB 1049 | 2.5~3.5 | ||

| Lighting impulse withstand voltage | GB 311 | 75KV/10 times | ||

| Peak / short time withstand current | GB 2706-89 | 31.5 KA/4s | ||

| 80.0 KA, peak | ||||

| Chemical | Flammability | ASTM D2863 | OI ≥ 27 | |

| Corrosion (23℃,humidity 95% for 4 hrs) | ASTM D2671 | Pass | ||

Product Image

UPM maufacturing plant front view

Frequently asked Q&A