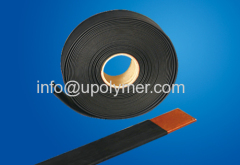

SS1-1 Bus Bar Insulation Heat Shrink Tube with shrink ratio 2:1 used in switchgear cabinets against accidential flashove

0.3~10.0 USD

| Min. Order: | 100 Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 40t/month |

| Place of Origin: | Liaoning |

Company Profile

| Location: | Dalian, Liaoning, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

Product Detail

| Means of Transport: | Ocean, Negotiable, Air, Land |

|---|---|

| Brand Name: | UPM heat shrink |

| Highest Working Temperature: | 125 ℃ |

| color: | Black |

| specification: | dia 15~175 mm |

| Shrink ratio: | 2:1,2.5:1,3:1 |

| Voltage class: | 600~1000V |

| Insulation ,sealing,protection: | Bus bar insulation and protection |

| Tel: | 86-411-87166661 |

| hot sale 2013: | Flame retardant thin wall cross-linked polyolefin |

| Contact: | Lily Zhang / info@upolymer.com |

| Flame retardant: | RoHS |

| Operating temperature:: | -40~105 ℃ |

| Production Capacity: | 40t/month |

| Packing: | standard carton packaging |

| Delivery Date: | within 3 weeks |

Product Description

SS1-1 Bus Bar Insulation Heat Shrink Tube

| ||||

| Features | ||||

| Flame retardant thin wall cross-linked polyolefin | Operating temperature: -40~105 ℃ | |||

| Bus bar insulation and protection | Shrink temperature: 125 ℃ | |||

| Reduces bus bar clearance requirement | Shrink ratio: 2:1 | |||

| Halogen free, RoHS compliant | Voltage class: 1KV | |||

| Protects against short circuit and electrical leakage caused by small animals | ||||

| Technical Data | ||||

| Property | Test method | Values | ||

| Physical | Tensile strength | ASTM D2671 | ≥14 MPa | |

| Breakdown elongation | ASTM D2671 | ≥400% | ||

| Aging (136℃/168hrs) | Tensile strength | ASTM D2671 | ≥12 MPa | |

| Breakdown elongation | ASTM D2671 | ≥300% | ||

| Resistance to selected fluids Tensile strength | IEC 60684-2 | ≥8MPa | ||

| (23℃/168hrs) Breakdown elongation | IEC 60684-2 | ≥250% | ||

| Density | ASTM D2671 | 1.15~1.25 | ||

| Thermal endurance | IEC 216 | 125 ℃ | ||

| Water absorption (23℃/336hrs) | ASTM D570 | ≤0.5% | ||

| Low temperature flexibility (-40℃/4hrs) | ASTM D2671 | No cracking | ||

| Heat shock (200℃/4hrs) | ASTM D2671 | No drop, No flow | ||

| Holdig air test | more than 3 | After shrink, no air gap | ||

| bendings on bus bar | between H.S.T. and bus bar | |||

| Cutting test (130℃/168hrs) | Raychem method | 5mm Length cutting along longitudinal, no cracking | ||

| Halogen free | IEC 61249-2-21 | Cl : 900ppm max.Br : 900ppm max. | ||

| Total(Cl + Br):1500ppm max. | ||||

| Electrical | Volume resistivity | ASTM D2671 | ≥1013 Ω.cm | |

| Dielectric strength(in insulation oil) | ASTM D2671 | ≥18 KV/mm | ||

| Chemical | Flammability | ASTM D2863 | OI≥ 27 | |

| Smoke index | IEC 61034 | ≤ 120 | ||

| Copper corrosion(158℃/168hrs) | IEC 60684-3 | Pass | ||

| Dimensions | |||||

| Reference | As supplied(mm) | After recovered(mm) | Standard length | ||

| UPM SS1-1 | ID min. | ID max. | WT nom. | m/spool | |

| 25/12 | 25 | 12 | 0.8 | 50 | |

| 30/15 | 30 | 15 | 0.8 | 50 | |

| 40/20 | 40 | 20 | 0.9 | 50 | |

| 50/25 | 50 | 25 | 0.9 | 25 | |

| 60/30 | 60 | 30 | 1 | 25 | |

| 70/35 | 70 | 35 | 1.1 | 25 | |

| 80/40 | 80 | 40 | 1.2 | 25 | |

| 90/45 | 90 | 45 | 1.3 | 25 | |

| 100/50 | 100 | 50 | 1.3 | 25 | |

| 120/60 | 120 | 60 | 1.3 | 25 | |

| 150/75 | 150 | 75 | 1.5 | 25 | |

| 180/90 | 180 | 90 | 1.5 | 25 | |

| Product selection | |||||

| Bus bar size (mm) | Single layer bus bar | Two layers bus bar | |||

| 20×3,25×3 | Φ25/12 | Φ30/15 | |||

| 30×3,30×4 | Φ30/15 | Φ40/20 | |||

| 30×10,40×4 | Φ40/20 | Φ50/25 | |||

| 40×10,50×5,50×6 | Φ50/25 | Φ60/30(Φ70/35) | |||

| 50×8,50×10,60×6,60×8 | Φ60/30 (Φ70/35) | Φ80/40 | |||

| 60×10,80×6,80×8,80×10 | Φ80/40 | Φ100/50(Φ120/60) | |||

| 100×8,100×10,100×12 | Φ100/50(Φ120/60) | Φ120/60 | |||

| 100×15,120×10,120×12,120×15 | Φ120/60 | Φ150/75 | |||

| 150×12,150×15 | Φ150/75 | Φ180/90 | |||

| ID=Internal Diameter | WT=wall thickness | ||||

| Typical application | |||||

| Suitable for insulation and protection of bus bar against accidental flashover up to 1 KV | |||||

| Ideal for using in switchgears cabinets where space is limited and air spacing between bus | |||||

| bars need to be kept at minimal | |||||

| Ordering | |||||

| Standard color : Black,Green | |||||

| Standard packaging on spools. | |||||

| Please specify specification, color, quantity when ordering | |||||

| Cross reference | |||||

| Raychem/ Tyco : LVIT | |||||