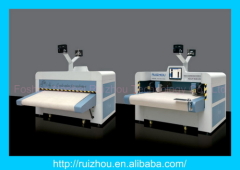

Ruizhou Dual-head CNC Knife Leather Cutting Machine

1.0~100000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 500 sets per year |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Foshan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | RZCUT-1530-2H |

|---|---|

| Means of Transport: | Ocean |

| Working Area: | 1.5*1m*3 |

| Production Capacity: | 500 sets per year |

| Packing: | standard export plywood case |

| Delivery Date: | within 60 days upon receipt of deposit |

Product Description

Dual-head CNC Knife Leather Cutting Machine

Ruizhou Dual-head CNC Knife Leather Cutting Machine combines three work areas in one machine, capable of nesting, cutting & collecting simutaneously. The conveyror belt further optimizes the work flow by the auto-feed function. With Ruizhou Dual-head CNC Knife Leather Cutting Machine, you can cut the materials continuously from nesting to collecting.

The dual cutting heads double the cutting speed. Ruizhou Dual-head CNC Knife Leather Cutting Machine is a machine can cut in high speed, high precision without interference and confliction.

Features:

1. CNC control system: Ruizhou Dual-head CNC Knife Leather Cutting Machine digitalizes the cutting processes, so frees you from moulds and dies, saving you lots of money. Ruizhou Dual-head CNC Knife Leather Cutting Machine also enlarges your products lines. You can design more complicated and exquisite patterns.

2. Smart nesting in section: for large skin or synthetic materials in rolls, the cutter has a new nesting function of dividing the whole piece of material into sections, allowing you to nest continuously and inter-sectionally. The converyor belt transports the nested section to the cutting area. The cutting system is able to recognize the sectional area to cut. In this way, Ruizhou Dual-head CNC Knife Leather Cutting Machine successfully avoids the waste of material which is caused by the limited nesting space of the table surface for large skin material and practically enhances the utilization rate of material by 5%.

3. Dual cutting heads work in opposite direction: Ruizhou Dual-head CNC Knife Leather Cutting Machine applies a multi-task operation system which makes the each cutting heads run in its own path without any confliction. Ruizhou Dual-head CNC Knife Leather Cutting Machine allows two separated tool heads cutting on difference with nesting and cutting process, thus enables the machine running on-stop.

4. Non-interference collecting: the rolling table makes collecting easy and quick, without causing any interfrence with nesting and cutting process.

5. High productivity: With two cutting tools running at the same time, the productivity is doubled. Ruizhou Dual-head CNC Knife Leather Cutting Machine can cut 800-1000 pairs of shoes a day.

6. Fast cutting: Ruizhou Dual-head CNC Knife Leather Cutting Machine adopts a hanging-arm abd sliding-rail design, which minimizes the friction against the tool heads and enables them to run smoothly and quickly. The speed of each head is increased by 100% compaired with one head cutter.

7. Practical solution: Ruizhou Dual-head CNC Knife Leather Cutting Machine combines nesting, cutting and collecting functions.

To better suit your cutting needs, we have 21 kinds of knives available:

8. Save time, material and space

| Technical parameters | Model No. | RZCUT-1530-2H |

| 1 | Characteristic | synchronic operation between computer and cutter, rapid data transmission which can be accessed to continuously |

| 2 | Cutting speed | 0-1.2m/s*2 |

| 3 | Cutting thickness | 0.1-4.0MM |

| 4 | Cutting materials | natural leather, artificial leather, cardboard, plastic board, complex materials, fiber sheet etc. |

| 5 | Cutting tool | rotating/ vibrating knife cutting tool, punching tool, pressing tool |

| 6 | Optional pen type | ordinary signing pen, oil pen, ball pen, silver pen |

| 7 | Suction method | vacuum suction based on cell |

| 8 | Machine resolution | 0.07mm |

| 9 | Software resolution | 0.025MM/0.01MM/0.1MM |

| 10 | Transmission Interface | standard serial interface/parallel port/ net port |

| 11 | Control system | Ruizhou CNC Leather Cutting System |

| 12 | Command system | Language of HP-GL and GP-GL |

| 13 | Control panel | touch control LCD display |

| 14 | Motor | servo motor |

| 15 | working area | 1500*1000mm*3 |

| 16 | Setup dimension | 3.14*2.45*2.34m |

| 17 | Host working voltage | AC 220V +/-10%, 50HZ |

| 18 | Vacuum pump working voltage | AC 380V +/- 10%, 50HZ |

| 19 | Oscillating knife tool | the motor of oscillaitng knife tool takes 12000-20000 rotate/min |