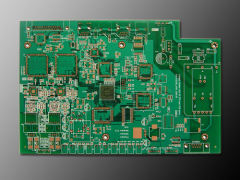

OEM pcb assembly service, SMT SMD PCBA

1.0~1000.0 USD

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 2000 Piece/Pieces per Day |

| Place of Origin: | Guangdong |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Plastic Mould Die Tooling, Controller Pcb Assembly, Mould Maker, Pcb Manufacturer, Plastic Injection Mould |

Product Detail

| Model No.: | pcba assembly service, SMT SMD PCBA |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Ridecon |

| Production Capacity: | 2000 Piece/Pieces per Day |

| Packing: | anti statics bubles bag, cartons. according to customer's requirement |

| Delivery Date: | 2 weeks |

Product Description

1, PCB Assembly (Lead Free PCB Assembly,RoHS):

2, Vision aligned solder paste deposition

3, 0201 to uBGA SMT placement capability

4, Pin In Paste (Intrusive Reflow)

5, High velocity forced hot air reflow systems

6, Light-guided work stations for conventional 'thru-hole' PCB assembly

7, Latest dual wave, flow soldering equipment

8, Programmable Selective Soldering

9, Analogue, Digital, RF and Functional test development, operation and debug In house FPGA and EPROM programming

10, Workmanship to IPC-610 class 3 or MIL STD 2000 equivalent

Final Product Assembly

Final Product Assembly

11, Assemble your printed circuit boards into finished product box assemblies

12, Provide cabinet, rack and backplane wired assemblies

13, Press-fit connectors into high density PCBs & Backplanes

14, Provide in house FPGA and EPROM programming facilities

15, Assemble complex cable forms & harnesses

16, Carry out potting, encapsulation and heat shrinking

17, Provide automated 'cut and strip' facilities to ensure accuracy of wire processing

18, Carry out semi-automated wire wrapping of complex assemblies

19, Provide service and repair facilities for product refurbishment and upgrade

20, Provide Functionality Testing,

21, Well package and storage and ready to ship

22, Generation of manufacturing control documents

22, Generation of manufacturing control documents

23, Early prototype build and design analysis

24, Design of test fixtures and software development

25, Unique product serializations