| No. | Test item | Test Result | |

| 1 | Heat seal temperature | 250-375℃ | |

| 2 | Heat seal time | 0.5-3.5Sec. | |

| 3 | Heat seal pressure | 30-70P.S.I | |

| 4 | Melt flow rate | ≥3.0g/min | |

| 5 | Volatile components | ≤0.50% | |

| 6 | Carrier | LDPE | |

| 7 | Melt index(g/10min) | 2.1 | |

| 8 | Density(g/cm) | 0.92g/cm | |

| 9 | Water abs orption rate | 0.50% | |

| 10 | Surface resistivity | 108-11Ω | |

| 11 | Size | (Envelop flap±5mm) length±5mm with±5mm GB/96-4-10 | |

| 12 | Appearance | No burst seal,wrinkle,break,foreign partical adherence | |

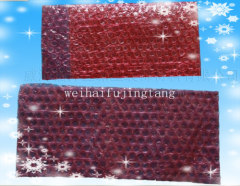

This product is made of polyethylene and applies to the packaging of light products.Being a kind of mature packaging material,it has good cushioning effect and shock reduction function through the sealed air bubble chambers.The anti-static air bubbles bag and air bubble sheet can prevent products from damage due to collision,attrition,or static during producition ordelivery process. With both the inner and surface resistance of 108-1010Ω, it is mainly used for the packaging of electronic components and PC boards.Its material structure,size and color can all be customized.

.jpg)