ASME B 16.5 duplex stainless steel flange

5.0~200.0 USD

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1,118,000 Tons / Year |

| Place of Origin: | Hebei |

Company Profile

| Location: | Cangzhou, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | ANSI Forged Stainless Socket Welding Flange, ANSI Forged Stainless Threaded Flange, ANSI Forged Stainless Steel Blind Flange, Concentrice Redueer Sch 5s BW ASTM A 403 WP304 MSS SP43, ANSI Forged Stainlessplate Flange |

Product Detail

| Model No.: | DN50 |

|---|---|

| Means of Transport: | Ocean, Land |

| Standard or Nonstandard: | Standard |

| Function: | Tyre Protection Chain |

| Material: | Stainless Steel |

| Brand Name: | GEE |

| Surface: | RF |

| standard: | ASME B 16.5 |

| material: | duplex stainless steel |

| pressure: | 150lb |

| Production Capacity: | 1,118,000 Tons / Year |

| Packing: | as the expore standards package |

| Delivery Date: | 7 after receipt of advanced payment |

Product Description

ASME B 16.5 duplex stainless steel flange

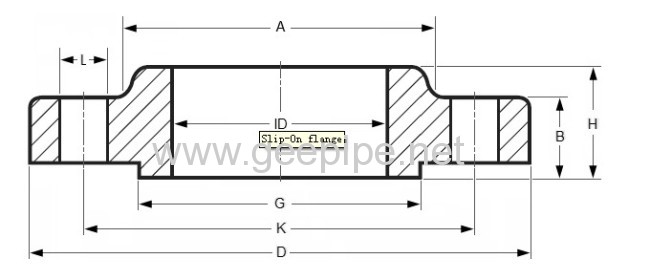

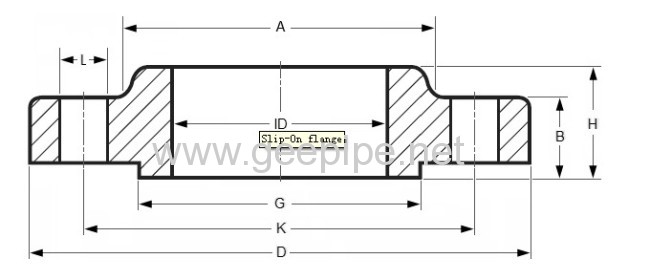

Dimensions and drawing of 2" Slip On FlangesASME B16.5

Gee products have four series: 1, flange and forged fittings; 2, the steeliness seamless butt weld fitting with steel plate, for example, elbows, tees, reducers, bends 3, seamless steel pipe, ERW, SSAW; 4, the nuclear project accessories. We also produce more than 3600 types pipeline accessories with 118 kinds of materials.

the GEE package .

he ASME B16.5 code requires that the flange face (raised face and flat face) has a specific roughness to ensure that this surface be compatible with the gasket and provide a high quality seal.

| Image of of serrated texture on Raised Face. |

A serrated finish, either concentric or spiral, is required with 30 to 55 grooves per inch and a resultant roughness between 125 and 500 micro inches. This allows for various grades of surface finish to be made available by flange manufactures for the gasket contact surface of metal flanges.

The most used Surfaces

Stock Finish

The most widely used of any flange surface finish, because practically, is suitable for all ordinary service conditions. Under compression, the soft face from a gasket will embed into this finish, which helps create a seal, and a high level of friction is generated between the mating surfaces. The finish for these flanges is generated by a 1.6 mm radius round-nosed tool at a feed rate of 0.8 mm per revolution up to 12 inch. For sizes 14 inch and larger, the finish is made with 3.2 mm round-nosed tool at a feed of 1.2 mm per revolution.

The most widely used of any flange surface finish, because practically, is suitable for all ordinary service conditions. Under compression, the soft face from a gasket will embed into this finish, which helps create a seal, and a high level of friction is generated between the mating surfaces. The finish for these flanges is generated by a 1.6 mm radius round-nosed tool at a feed rate of 0.8 mm per revolution up to 12 inch. For sizes 14 inch and larger, the finish is made with 3.2 mm round-nosed tool at a feed of 1.2 mm per revolution.

Spiral Serrated

This is also a continuous or phonographic spiral groove, but it differs from the stock finish in that the groove typically is generated using a 90-deg tool which creates a "V" geometry with 45° angled serration.

This is also a continuous or phonographic spiral groove, but it differs from the stock finish in that the groove typically is generated using a 90-deg tool which creates a "V" geometry with 45° angled serration.

Concentric Serrated

As the name suggests, this finish is comprised of concentric grooves. A 90° tool is used and the serrations are spaced evenly across the face.

As the name suggests, this finish is comprised of concentric grooves. A 90° tool is used and the serrations are spaced evenly across the face.

Smooth Finish

This finish shows no visually apparent tool markings. These finishes are typically utilized for gaskets with metal facings such as double jacketed, flat steel and corrugated metal. The smooth surfaces mate to create a seal and depend on the flatness of the opposing faces to effect a seal. This is typically achieved by having the gasket contact surface formed by a continuous (sometimes called phonographic) spiral groove generated by a 0.8 mm radius round-nosed tool at a feed rate of 0.3 mm per revolution with a depth of 0.05 mm. This will result in a roughness between Ra 3.2 and 6.3 micrometers (125 - 250 micro inch).

This finish shows no visually apparent tool markings. These finishes are typically utilized for gaskets with metal facings such as double jacketed, flat steel and corrugated metal. The smooth surfaces mate to create a seal and depend on the flatness of the opposing faces to effect a seal. This is typically achieved by having the gasket contact surface formed by a continuous (sometimes called phonographic) spiral groove generated by a 0.8 mm radius round-nosed tool at a feed rate of 0.3 mm per revolution with a depth of 0.05 mm. This will result in a roughness between Ra 3.2 and 6.3 micrometers (125 - 250 micro inch).

Remark(s) of the Author...

SMOOTH FINISH

Is it suitable for spiral gasket and non metallic gasket?

For what kind of application is this type?

For what kind of application is this type?

The above questions are often asked. I try to answer.

Smooth finish flanges are more common for low pressure and/or large diameter pipelines and primarily intended for use with solid metal or spiral wound gaskets.

Smooth finishes are usually found on machinery or flanged joints other than pipe flanges. When working with a smooth finish, it is important to consider using a thinner gasket to lessen the effects of creep and cold flow. It should be noted, however, that both a thinner gasket and the smooth finish, in and of themselves, require a higher compressive force (i.e. bolt torque) to achieve the seal.

You may have probably seen this comment:

Machining of gasket faces of flanges to a smooth finish of Ra = 3.2 - 6.3 micrometer

(= 125 - 250 microinches AARH)

Machining of gasket faces of flanges to a smooth finish of Ra = 3.2 - 6.3 micrometer

(= 125 - 250 microinches AARH)

AARH stands for Arithmetic Average Roughness Height. It is used to measure the roughness (rather smoothness) of surfaces. 125 AARH means 125 micro inches will be the average height of the ups and downs of the surface.

63 AARH is specified for Ring Type Joints.

125-250 AARH (it is called smooth finish) is specified for Spiral Wound Gaskets.

250-500 AARH (it is called stock finish) is specified for soft gaskets such as NON Asbestos, Graphite sheets, Elastomers etc. If we use smooth finish for soft gaskets enough "biting effect" will not occur and hence the joint may develop leak.

Sometimes AARH is referred also as Ra which stands for Roughness Average and means the same.

Dimensions and drawing of 2" Slip On FlangesASME B16.5

Size :DN50

pressure:150#

standard :ASME B 16.5

standard :ASME B 16.5

Material:UNS S32750

surface: RF

country of origin :China

Brand: GEE

Technics: heat treatment

Connection: welding

Qualification: ISO9001/API/CE/BV/ABS/The famous trademark of china

Gee products have four series: 1, flange and forged fittings; 2, the steeliness seamless butt weld fitting with steel plate, for example, elbows, tees, reducers, bends 3, seamless steel pipe, ERW, SSAW; 4, the nuclear project accessories. We also produce more than 3600 types pipeline accessories with 118 kinds of materials.

the GEE package .