SC40X100 Standard Air Cylinder

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 100000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | SC40X100 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | FL |

| Acting Type: | Double Acting |

| Fluid Medium: | Air |

| Pressure Range: | 0.05Mpa--0.8Mpa(7.3--116Psi) |

| Proof Pressure: | 1.35MPa(195psi) |

| Working Temperature: | 0--70℃ |

| Working Speed Range: | 50--800 mm/s |

| Cushion: | Adjustable Cushion |

| Adjustable Cushion Stroke: | 20mm |

| Port Size: | G1/4 |

| Origin: | China |

| Production Capacity: | 100000 |

| Packing: | In Cartons |

| Delivery Date: | Negotiable |

Product Description

Pneumatic cylinders (sometimes known as air cylinders) are mechanical devices which utilize the power of compressed gas to produce a force in a reciprocating linear motion.

Like hydraulic cylinders, pneumatic cylinders use thestored potentialenergy of a fluid, in this case compressed air, andconvert it intokinetic energy as the air expands in an attempt to reachatmosphericpressure. This air expansion forces a piston to move in thedesireddirection. The piston is a disc or cylinder, and the pistonrodtransfers the force it develops to the object to be moved. Engineersprefer to use pneumatics sometime because they are quieter, cleaner,anddo not require large amounts or space for fluid storage.

Product Name: SC40X100 Standard Air Cylinder

---------SC40X100 Pneumatic Air Cylinder

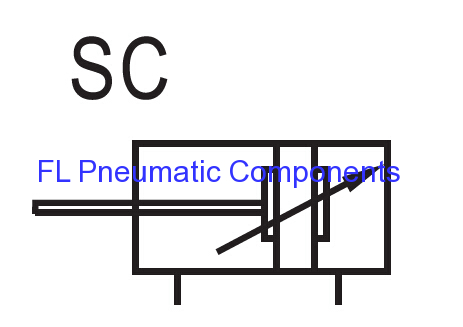

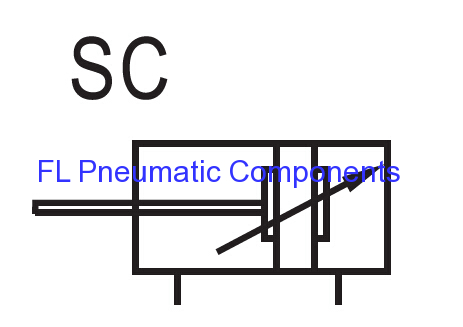

Symbol of FL Standard Air Cylinder:

Specification of SC Series Air Cylinder:

Stroke of SC Series Pneumatic Cylinder:

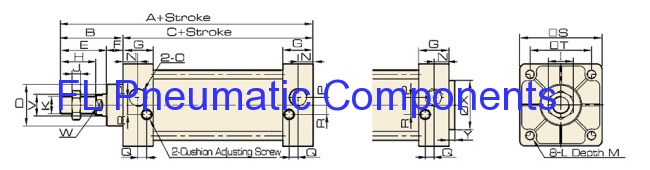

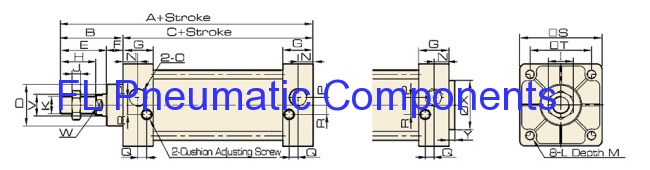

Dimension of Airtac SC Series Air Cylinder:

Structure of China SC Series Air Cylinder:

Like hydraulic cylinders, pneumatic cylinders use thestored potentialenergy of a fluid, in this case compressed air, andconvert it intokinetic energy as the air expands in an attempt to reachatmosphericpressure. This air expansion forces a piston to move in thedesireddirection. The piston is a disc or cylinder, and the pistonrodtransfers the force it develops to the object to be moved. Engineersprefer to use pneumatics sometime because they are quieter, cleaner,anddo not require large amounts or space for fluid storage.

Product Name: SC40X100 Standard Air Cylinder

---------SC40X100 Pneumatic Air Cylinder

Symbol of FL Standard Air Cylinder:

Specification of SC Series Air Cylinder:

| Bore | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | 200 | 250 | 320 | |

| Operation Type | Double Acting | |||||||||||

| Working Medium | Air | |||||||||||

| Pressure Range | 0.05Mpa--0.85Mpa(7.3--123Psi) | |||||||||||

| Proof Pressure | 1.35MPa(217psi) | |||||||||||

| Working Temperature | 0--70℃ | |||||||||||

| Working Speed Range | 50--800 mm/s | |||||||||||

| Cushion | Adjustable Cushion | |||||||||||

| Adjustable Cushion Stroke | 20mm | 26mm | 45mm | 52mm | 66mm | |||||||

| Port Size | G1/8 | G1/4 | G3/8 | G1/2 | G3/4 | G1 | ||||||

| Mounting Accessories | SC | BASIC, FA, FB, CA, CB, LB, TC, TC-M | ||||||||||

| SCD,SCJ | FA, FB, CA, CB, LB, TC, TC-M | |||||||||||

Stroke of SC Series Pneumatic Cylinder:

| Bore | Standard Stroke | Max. Stroke | Allowable Stroke |

| 32 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 | 1000 | 2000 |

| 40 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 | 1200 | 2000 |

| 50 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1200 | 2000 |

| 63 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 80 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 100 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 125 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 160 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 200 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 250 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 320 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

Dimension of Airtac SC Series Air Cylinder:

| Bore/Symbol | A | A1 | A2 | B | C | D | E | F | G | H | I | J | K | L |

| 32 | 140 | 187 | 182 | 47 | 93 | 28 | 32 | 15 | 27.5 | 22 | 17 | 6 | M10 x 1.25 | M6 |

| 40 | 142 | 191 | 185 | 48 | 93 | 32 | 34 | 15 | 27.5 | 24 | 17 | 7 | M12 x 1.25 | M6 |

| 50 | 150 | 207 | 196 | 57 | 93 | 38 | 42 | 15 | 27.5 | 32 | 23 | 8 | M16 x 1.5 | M6 |

| 63 | 153 | 210 | 199 | 57 | 96 | 38 | 42 | 15 | 27.5 | 32 | 23 | 8 | M16 x 1.5 | M8 |

| 80 | 183 | 258 | 243 | 75 | 108 | 47 | 54 | 21 | 33 | 40 | 26 | 10 | M20 x 1.5 | M10 |

| 100 | 189 | 264 | 249 | 75 | 114 | 47 | 54 | 21 | 33 | 40 | 26 | 10 | M20 x 1.5 | M10 |

| 125 | 226 | / | / | 104 | 122 | 55 | 70 | 34 | 33 | 54 | 40 | 10 | M27 x 2 | M12 |

| 160 | 291 | / | / | 123 | 168 | 62 | 93 | 40 | 50 | 72 | 55 | 18 | M36 x 2 | M16 |

| 200 | 347 | / | / | 167 | 180 | 80 | 112 | 55 | 50 | 72 | 55 | 18 | M36 x 2 | M16 |

| 250 | 389 | / | / | 189 | 200 | 90 | 122 | 67 | 54 | 84 | 65 | 21 | M42 x 2 | M20 |

| 320 | 436 | / | / | 216 | 220 | 110 | 126 | 90 | 65 | 96 | 75 | 24 | M48 x 2 | M24 |

| Bore/Symbol | M | N | O | P | Q | R | S | T | V | W | Z | X | Y |

| 32 | 9.5 | 13.5 | G1/8 | 3.5 | 7.5 | 7 | 45 | 33 | 12 | 10 | 21 | / | / |

| 40 | 9.5 | 13.5 | G1/4 | 6 | 8.2 | 9 | 50 | 37 | 16 | 14 | 21 | / | / |

| 50 | 9.5 | 13.5 | G1/4 | 8.5 | 8.2 | 9 | 62 | 47 | 20 | 17 | 23 | / | / |

| 63 | 9.5 | 13.5 | G3/8 | 7 | 8.2 | 8.5 | 75 | 56 | 20 | 17 | 23 | / | / |

| 80 | 11.5 | 16.5 | G3/8 | 10 | 9.5 | 14 | 94 | 70 | 25 | 22 | 29 | / | / |

| 100 | 11.5 | 16.5 | G1/2 | 11 | 9.5 | 14 | 112 | 84 | 25 | 22 | 29 | / | / |

| 125 | 15.5 | 16.5 | G1/2 | 10 | 10 | 11 | 140 | 110 | 32 | 27 | / | / | / |

| 160 | 17.5 | 25 | G1/2 | / | / | / | 180 | 140 | 40 | 36 | / | / | / |

| 200 | 17.5 | 25 | G3/4 | / | / | / | 220 | 175 | 40 | 36 | / | / | / |

| 250 | 25 | 31 | G1 | 18.5 | 5 | 40 | 270 | 220 | 50 | 46 | / | 90 | 10 |

| 320 | 28 | 31 | G1 | 35 | 15 | 35 | 350 | 270 | 63 | 55 | / | 110 | 10 |

Structure of China SC Series Air Cylinder:

| No. | Name | Material |

| 1 | Front Cover | Painted Aluminum |

| 2 | Back Cover | Painted Aluminum |

| 3 | Barrel | Anodised Aluminum |

| 4 | Piston Rod | Chromed Carbon Steel |

| 5 | Piston | Aluminum |

| 6 | Piston Rod Seal | NBR |

| 7 | Piston Seal | NBR |

| 8 | Bearing | Non-lub Bearing |

| 9 | Magnet | Plastic |

| 10 | Cushion Screw | Brass |

| 11 | Anti-frintion Ring | PTFE |

| 12 | End Cap Seal | NBR |

| 13 | Cushion Seal | NBR |

.jpg)