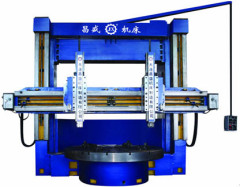

CK5280 CNC Double column vertical lathe

| Place of Origin: | Liaoning |

|---|

Company Profile

| Location: | Dalian, Liaoning, China (Mainland) |

|---|---|

| Business Type: | Trading Company, Agent, Distributor/Wholesaler |

Product Detail

| Model No.: | CK5280 CNC Double column vertical lathe |

|---|---|

| Brand Name: | ZH |

| TEL: | 86-411-84113739 |

| Mobile: | 8613478653566 |

| Email: | sales@vertical-lathes.net |

| MSN: | sales@vertical-lathes.net |

| Yahoo messager: | verticallathes@yahoo.cn |

| SKYPE: | verticallathes |

Product Description

CNC double column vertical lathes

CNC Vertical Lathe Numerical control system is Siemens or Fanuc CNC.

Bring in finite element analysis,specially designed aiming at high efficiency,high rigidity,heavy cutting etc working conditions.

1 The pillar and base plate both use big-size box arrangement,offering the biggest Z shaft ram section with 230*200 size,can support over heavy cutting.

2 The symmetrical layout can reasonably avoiding heat deformation,reasonable arrangement and many times of temper and aging processings,has guaranteed a long time stability for the lathe's accuracy.

3 The radial direction of main shaft use P4 level double column roller bearing,the axial direction use P4 level big size thrust bearing,at the same time of ensuring high rotating accuracy,the high load capacity has also been ensured.

4 The hydraulic system use machine-outside cycling,which can take away the heat efficiently.The oil pump is always in a unloading state to avoid the lathes' temperature rise.When the lathe is equipped with second main shaft,the lathe is equipped with oil cooler.

5 Big diameter ball screw,X shaft ball screw pre-stretching,which has ensured a high position accuracy and can compensate heat deformation.

6 The lathe has big openings,which is convenient for components handling,loading and unloading.the operate button face can have a

90°turning,good agreeableness.

7 There have kinds of configurations for users to choose from,like standard type,heavy load type and high speed type.Also we can choose ZF two-section transmission case or our company's four-section transmission case on the basis of users requirement.