high energy efficiency Microwave Atmosphere Furnace

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 10sets/month |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | EF-QS |

|---|---|

| Means of Transport: | Ocean |

| Type: | Microwave Furnace |

| Usage: | Advanced ceramics equipment |

| Brand Name:: | EasyFashion |

| Processing Type: | : Machining Equipment |

| Production Capacity: | 10sets/month |

| Packing: | standard export wooden cases |

| Delivery Date: | 30~90days |

Product Description

Microwave Atmosphere Lab Furnace

Production

1.Overview

1. It's suitable for various technological research, such as synthesis, roasting, heat treatment, sintering,etc.

2. It adopts pre-vacuum method to save the time of replacement atmosphere.

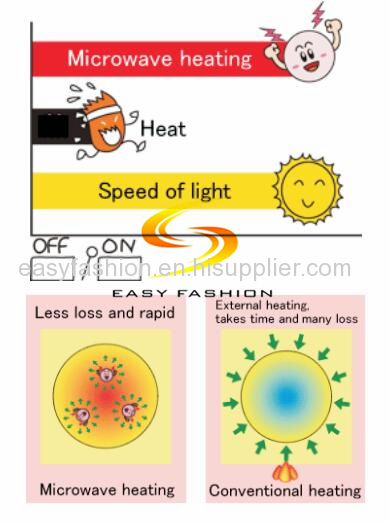

3. Rapid heating increases lab efficiency.

4.Large sintering area, good uniformity and small output capacity available

2.Specifications

Item | Model | EF-MALF-01 | EF-MALF-02 |

Power | Voltage | 220±10V, 50Hz, 3 phase | 220±10V, 50Hz, 3 phase |

Rated power | 6KW | 6KW | |

Microwave system | Microwave output power | 0.01~1.40KW continuously adjustable | 0.01~1.40KW continuously adjustable |

Microwave frequency | 2.45GHz | 2.45GHz | |

Thermal insulation system

| Ultimate temperature | 1200°C | 1650°C |

Continuously working temperature | 1150°C | 1580°C | |

Heating zone | 150×110×70mm(L×W×H) | 130×80×70mm(L×W×H) | |

Heating rate | Rapid heating; average heating rate ≥20°C/min. | Rapid heating; average heating rate is ≥20°C/min. | |

Temperature control system | Temperature measurement method | Thermocouple | Thermocouple |

Temperature measurement range | 0~1300°C | 300~1800°C | |

Temperature control precision | ±0.1% | ±0.1% | |

Control system | Automatic, manual and thermostatical control methods | 40 programmable technology curves available; curve real-time display; data storage and export; dynamic data on the screen | 40 programmable technology curves available; curve real-time display; data storage and export; dynamic data on the screen |

Atmosphere system | Static ultimate vacuum degree | ≤100Pa | ≤100Pa |

Vacuum units, two way atmosphere control line | Fast pre-vacuum; atmosphere options:oxidizing gas, inert gas, weak reducing gas etc. | Fast pre-vacuum; atmosphere options: oxidizing gas, inert gas, weak reducing gas etc. | |

Safety system | Microwave leakproof | Microwave leak level<0.5mW/cm2 | Microwave leak level<0.5mW/cm2 |

Magnetron alarm | Overheating alarm, over-current alarm | Overheating alarm, over-current alarm | |

Furnace door protection alarm | Furnace door shutdown protection switch | Furnace door shutdown protection switch | |

Cooling water alarm | / | Flow alarm | |

Cooling system | High precision chiller | / | Flow rate 2m3/h; rated cooling |

Overall dimension | Main furnace | 1150×850×800mm (L×W×H) | 1150×850×800mm (L×W×H) |

Floor space | 1m2 | 2m2 |

3.Features

1.Dedicated microwave source system of high energy efficiency and long service life to ensure 24 hours continuous stable working;

2.Intelligent control on microwave ouput power by PLC programmable control system;

3.Operation mode of manual, automatic and constant temperature available;

4.Microwave heating technology curve displayed online, and data storage, output and edited to facilitate analysis;

5.Optimized fire-resisting construction and various microwave fire-resisting materials combined to enhance properties of high temperature resistance, wave transmission and intensity, and solve thermal losses caused by thermal expansion;

6.Furnaces serialized and standardized, and accessories available upon request;

7.Almost no microwave leakage in operation position.

Packaging and Shipping

Commpany Information

Commpany Information

EasyFashion is the multifaceted manufacturer of atomization powder manufacturing equipment and thermal processing equipment.We take pride in offering diversified product range which comprises powder production equipment,sintering furnaces,microwave furnaces,heat treatment furnaces etc.

Our efforts have always been focused on reducing purchase cost and minimizing investment risk for customers in industries of MIM (metal injection molding), acuum heat treatment, powder metallurgy, atomization powder manufacturing,carbon and silicon carbide materials, as well as amorphous materials, photovoltaic materials and Li-ion battery materials, etc.

Patent

Patent

Customer Case

Customer Case

FAQ

1. How can I know your factory can produce equipment I need?

Re: Contact us and let us know your requirements of equipment. Then we will send these requirements to our technical department. So we will know whether our factory can offer you equipment or not.

2. Does your company customize equipment for customer?

Re: Yes, we can customize equipment according to customers' requirements.

3. Are you a trade company or a factory?

Re: We are a manufacturer with a huge factory. Warmly welcome to visit our factory and contact with us.

4. How can I believe your quality?

Our equipment are eqquiped with mechanical parts of world renowned brands like Schneider, Omron and so on, and also approved ISO9001 certification.

SEND US AN INQUIRY NOW !