vacuum hot pressing sintering furnace hot isostatic pressing sintering furnace

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 10sets/month |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Type: | Resistance Furnace |

| Usage: | Advanced ceramics equipment |

| Production Capacity: | 10sets/month |

| Packing: | standard export wooden cases |

| Delivery Date: | 120days |

Product Description

Hot Isostatic Press Sintering Furnace

Product Description

1.Overview

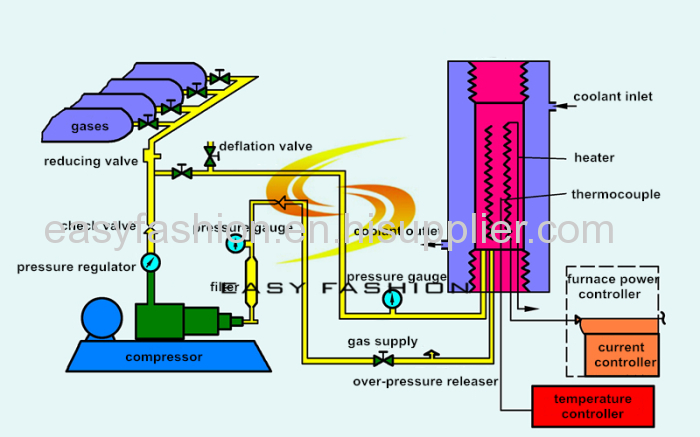

HIP (Hot Isostatic Press) is an advanced sintering technology and combines debinding, sintering and densification into an integrated cycle. Identical pressure is carried on specimen under high temperature and high pressure. It results in a product that contains little or no porosity, thereby producing a component that is as close to full theoretical density as possible.

2.Specifications

Model | Hot Zone(mm) | Max.Temperature | Working Pressure | Heating Element | Atmosphere |

EF-R | 500*500 | 900 | 60 | Cr20Ni80 | Ar |

EF-S | 150*300 | 1450 | 100 | Molybdenum | Ar |

EF-T | 125*200 | 2000 | 120 | Graphite | Ar |

Note:upgrade configuration upon request

3.Features

1.High density and high uniformity

2.Short production cycle and low energy saving

3.Outstanding properties

Customer Case

Russian Group Visited Us for Purchasing Sinter HIP Furnace

2016-11-28

New order - HIP furnace was concluded this week! Today Russian customers signed contract and sent down-payment to us for purchasing Sintering HIP furnace.

The following is the technical parameters of the equipment:

Max. loading: 500KG

Max. design pressure: 6Mpa

Max. working temperature: 1550C

Max. Vacuum: ≤ 2Pa

Packaging & Shipping

Company Information

EasyFashion is the multifaceted manufacturer of atomization powder manufacturing equipment and thermal processing equipment.We take pride in offering diversified product range which comprises powder production equipment,sintering furnaces,microwave furnaces,heat treatment furnaces etc.

Our efforts have always been focused on reducing purchase cost and minimizing investment risk for customers in industries of MIM (metal injection molding), acuum heat treatment, powder metallurgy, atomization powder manufacturing,carbon and silicon carbide materials, as well as amorphous materials, photovoltaic materials and Li-ion battery materials, etc..

Patent

Customers

FAQ

1. How can I know your factory can produce equipment I need?

Re: Contact us and let us know your requirements of equipment. Then we will send these requirements to our technical department. So we will know whether our factory can offer you equipment or not.

2. Does your company customize equipment for customer?

Re: Yes, we can customize equipment according to customers' requirements.

3. Are you a trade company or a factory?

Re: We are a manufacturer with a huge factory. Warmly welcome to visit our factory and contact with us.

4. How can I believe your quality?

Our equipment are eqquiped with mechanical parts of world renowned brands like Schneider, Omron and so on, and also approved ISO9001 certification.

SEND US AN INQUIRY NOW !