Hot sale copper powder water atomization manufacturing equipment

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 10sets/month |

| Place of Origin: | Hunan |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Type: | Resistance Furnace |

| Usage: | Sintering Furnace |

| Production Capacity: | 10sets/month |

| Packing: | standard export wooden cases |

| Delivery Date: | 30~90days |

Product Description

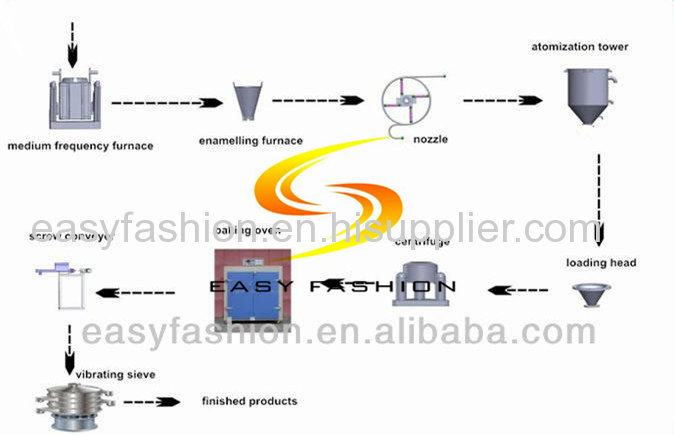

Water Atomization Powder Manufacturing Equipment

Product Description

1.Overview

The water atomization powder manufacturing equipment is the commercially progressive methodology in powder metallurgy industry. This kind of powder production machine utilizes high velocity water flow to atomize molten metal into powder particles. It's highly recommended for production of iron powder, copper powder, stainless steel powder and alloy powder.

Our water atomization powder manufacturing equipment produces 10~1,000kg powder per batch. It's also can produce alloy powders, such as iron-based powder, nickel-based powder, copper-based powder, silver-based powder, etc.. Moreover, customized equipment is also available to cater to customer's specific requirements on batch capacity and particle size.

2.Specifications

Model | EFSWH-30 | EFSWH-50 | EFSWH-100 | EFSWH-300 | EFSWH-500 | EFSWH-1000 | ||||

High-pressure water pressure(MPa) | 30-120 | |||||||||

High-pressure water flow(L/min) | 50-800 | |||||||||

Furnace weight (kg) | 30 | 50 | 100 | 300 | 500 | 1000 | ||||

Highest smelting temperature | 1750 | |||||||||

Smelt heating power (kW) | 50 | 100 | 160 | 300 | 400 | 600 | ||||

Temperature measuring method | Infrared thermometer, WRe5.26 | |||||||||

Tunish heating power (kW) | 20-45 | |||||||||

Power supply | 3 phases, 380V, 50Hz | |||||||||

Installed total power (kW) | Different based on different capacity and configuration | |||||||||

Cooling water flow (L/min) | 150 | 300 | 400 | 700 | ||||||

Cooling water device | Fan cooling tower, water cooling unit, heat exchanger | |||||||||

Soft water flow (m3/h) | 6-20 | |||||||||

Control mode | Industrial control computer or PLC | |||||||||

Operation interface | Touch-tone or Touch-screen | |||||||||

Data recording | 12 data-curve recording, LCD monitoring display | |||||||||

Appearance size | 7500x4000x | 7500x4200x | 8200x5200x | 9200x6500x | 9500x6500x | 10000x7000x | ||||

3.Features

The atomized powder produced by the equipment is irregular with relatively high content of oxygen. Oxygen content can be reduced by the subsequent reduction process.

We also offer the whole water atomizing production line, including water atomization powder manufacturing equipment, reduction furnace, nitrogen circulating system, ball mill machine, sieving machine, mixing machine etc..

Customer Case 1

High Pressure Water Atomization Powder Manufacturing Equipment in Japan

In 2012, A company from Japan contacted us through its sales agent about high pressure water atomization powder production equipment. After mutual communication and field study, cooperative relationship was established at last. Our technical team went to Japan to provide installation debugging and training service in

1. Capacity: 30KG/batch(stainless steel)

2. Melting temperature: max. 1700°C

3. Max. atomizing pressure: 100MPa

4. Powder shape: near spherical or irregular

5. Finished powder: superfine stainless steel powder -325 mesh≥90%

Customer Case 2

High Pressure Water Atomization Powder Manufacturing Production Line in Estonia

In 2010, we have kept in touch with a company in Estonia for a year! And finally cooperative relationship was established. After the equipment was produced, our technicians went to their plant to provide installation instruction and training, thus the produced powder met parameter requirements of the customer.

The exported high pressure water atomization powder manufacturing production line has the following basic parameters:

1. Capacity: 100kg/batch;

2. Max. melting temperature: 1700°C;

3. Ultimate atomizing pressure: 50MPa;

4. Powder shape: near spherical or irregular;

5. Rate of finished powder: take stainless steel as example: below -325mesh≥60%; below -200mesh≥80%

Customer Case 3

Totally Automatic High Pressure Water Atomization Powder Manufacturing Production

In 2014, a Taiwan company contacted us about the whole solution for copper powder production. We proposed an exclusive production line solution based on the customer's requirements. Finally we established mutual cooperation relations in 2015. At present the production line has already in production.

The totally automatic high pressure water atomization powder manufacturing production line has the following basic parameters:

1. Capacity: 200kg/batch

2. Max. melting temperature: 1500°C;

3. Rated powder: 200kW; Intermediate Frequency: About 1000Hz; Power: 380V, 60Hz

4. Limited atomizing pressure: 76MPa

5. Power morphology: irregular or subsphaeroidal

6. Rate of finished powders (accepted by pure copper powder): -325mesh(45μm)≥70%; -200mesh(75μm)≥90%

Packing and Shipping

Company Information

EasyFashion is the multifaceted manufacturer of atomization powder manufacturing equipment and thermal processing equipment.We take pride in offering diversified product range which comprises powder production equipment,sintering furnaces,microwave furnaces,heat treatment furnaces etc.

Our efforts have always been focused on reducing purchase cost and minimizing investment risk for customers in industries of MIM (metal injection molding), acuum heat treatment, powder metallurgy, atomization powder manufacturing,carbon and silicon carbide materials, as well as amorphous materials, photovoltaic materials and Li-ion battery materials, etc.

Patent

FAQ

1. How can I know your factory can produce equipment I need?

Re: Contact us and let us know your requirements of equipment. Then we will send these requirements to our technical department. So we will know whether our factory can offer you equipment or not.

2. Does your company customize equipment for customer?

Re: Yes, we can customize equipment according to customers' requirements.

3. Are you a trade company or a factory?

Re: We are a manufacturer with a huge factory. Warmly welcome to visit our factory and contact with us.

4. How can I believe your quality?

Our equipment are eqquiped with mechanical parts of world renowned brands like Schneider, Omron and so on, and also approved ISO9001 certification.

SEND US AN INQUIRY NOW !