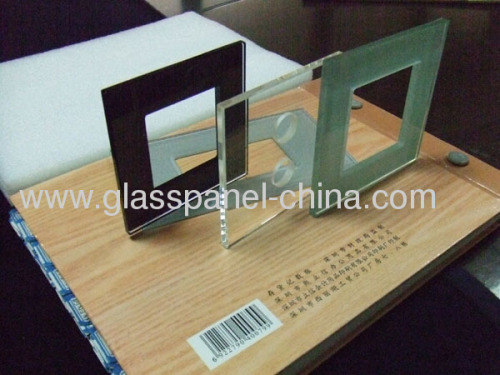

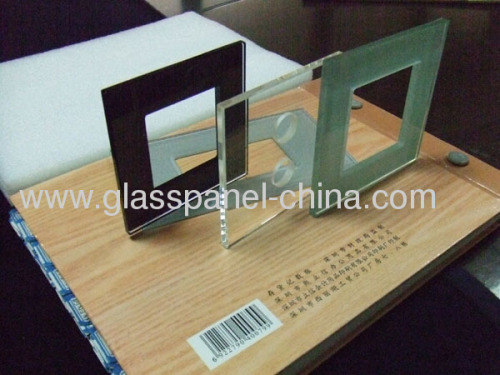

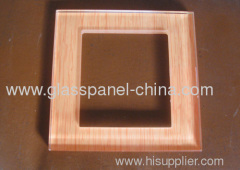

glass switch panel

1.0~20.0 USD

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Payment Terms: | T/T, WU |

| Supply Ability: | 50000/month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

| Main Products: | Rear-view Mirror, Glass Switch Cover(panel), Marble Switch Cover (panel), Bedside Switch Cover, Glass Touch Light Switch |

Product Detail

| Model No.: | custom-made |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | customization |

| Size: | any |

| Max. Current: | 10A |

| Max. Voltage: | 250V |

| Mechanical Life: | 10000times |

| Production Capacity: | 50000/month |

| Packing: | canton or wooden box |

| Delivery Date: | 20-40 days |

Product Description

At China, we've been making high quality glass wall switch covers since 2004 from our production facility in Shenzhen, GuangDong. Our products are a far cry from the

bland white and cream wall switch plates you see on most walls. They are stylish, decorative and custom-made glass switch plates for your walls. We use a wide variety

of finishes, styles, and materials to accent and beautify your rooms.

We are a glass processing enterprise, our main products include edge polished glass, silkscreen glass, flat tempered glass and other products. Our products are widely used in touch switches, mechanical switch crystal panel series, the hotel intelligence control systems terminal panels , intelligent home control terminal panel and other fields. It is the best alternative of the traditional injection moulding and aluminum panels.Our tenet and philosophy is: To provide high quality products and high level services for our customers all the way.All products of the company are based on customers' drawings or to request customization.

Our tenet and philosophy is:

To provide high quality products and high level services for our customers all the way.

All products of the company are based on customers' drawings or to request customization.

Float glass is a sheet of glass made by floating molten glass on a bed of molten tin. This method gives the sheet uniform thickness and very flat surfaces.

Production Process: The raw materials (soda lime glass, silica sand, calcium, oxide, soda and magnesium) are properly weighted and mixed and then introduced into a furnace where they are melted at 1500° C. The molten glass then flows from the glass furnace onto a bath of molten tin in a continuous ribbon. The glass, which is highly viscous, and the tin, which is very fluid, does not mix so that the contact surface between these two materials is perfectly flat. When leaving the bath of molten tin the glass has cooled down sufficiently to pass to an annealing chamber called a lehr. Here it is cooled under controlled temperatures, until it is essentially at room temperature.

.jpg)