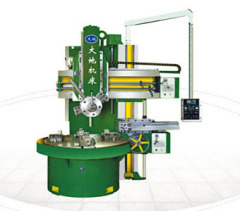

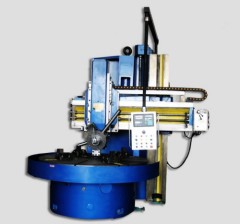

C5112E Single Column Vertical Lathe

| Place of Origin: | Liaoning |

|---|

Company Profile

| Location: | Dalian, Liaoning, China (Mainland) |

|---|---|

| Business Type: | Trading Company, Agent, Distributor/Wholesaler |

Product Detail

| Model No.: | C5112E Single Column Vertical Lathe |

|---|---|

| Brand Name: | ZhengHe |

Product Description

C5112E Single Column Vertical Lathe Machinevertical lathe has excellent quality,which can be No.1 in China.

Both the crossbeam guide rail and ram guide rail are processed by the super

audio quench(HRC≥50), the sliding surface of guide rail is processed by model sticked(including oblique iron surface and plate surface ),the product's accuracy can stay for a long time,at least may extend the huge mend cycle to up 10 years

All the casting used on the lathe is HT300,with manual heat timeliness processed.All the casting will never do any lose weight processings,the whole body's weight is match up to the standard weight.

The pentagon knife table adopts high accuracy mouth-tooth plate to positioned.Each of the 120 parts positioned separately,greatly strengthened rigidity.

The lathe is standard equipped with 4 axis digital displayed,electricity uses Japan Omron PLC controlled,all the electric parts are uses super high quality components,standard(CE standard) wiring craft,so the whole machine's electricity has high reliability.Electronic valve,16 level mechanical speed changing,convenient,flexible and reliable.High accuracy grinding gears and grinding spiral umbrella(level 6 accuracy),low noise and translation motion.

Both the lathes design and manufacture are strictly according to JB/T4116-96 vertical lathe accuracy test standard and JB/3665-96 vertical lathe technical conditions.

For completed accessories configuration,the users can go into production when only well prepared knife tools and measure tools.Completed after sales service(before sales,in sales,after sales,installation,debugging,training and repair guaranteed),one year quality guaranteed.

Optional configurations:rolling worktable,Germany Mecano button station,higher lathe bed,lengthen ram,square ram,etc.