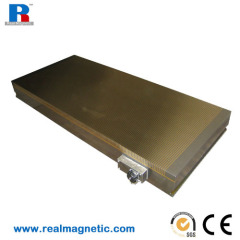

1000*600 Electro-permanent Magnetic Chuck

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Magnetic Workholding, Quick Mould Clamping System, Electro Permanent Magnetic Chucks, Magnet Chuck, Injection Clamping System |

Product Detail

| Model No.: | DMEPC50 |

|---|---|

| Means of Transport: | Ocean |

| Brand name: | MaxMagnet |

| Chuck size: | 1000*600 |

| Pole number: | 150 |

| Pole size: | 50*50 |

| Magnetic force: | 300kg/pole |

| Function: | workholding |

| Control mode: | CNC |

| Magnetization output time: | 0.1--0.9S |

| Production Capacity: | 100sets/month |

| Packing: | wooden case |

| Delivery Date: | 30 days |

Product Description

electro magnet chuck

It's widely applied to attract workpieces in surface grinders, electric processing machine-tools, as well as in casting, drilling, planning and boring machines. Besides, it's used in accessory holders for processing centers and FMS systems.

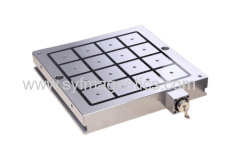

Permanent-electro magnetic Chuck controller: There are one-way, two-way and four-way channels to be chosen in our company and we can design more multi-way controllers such as 8-way,16-way according to customers' requirements.

The standard series of chucks include more versions which have different performance characteristics. Capable of adapting to different operating needs, depending on the thickness. The surface condition (or the operating air gap) and the dimensions of the work piece to be clamped. The clamping force of each version depends on the different dimension types of poles and on the configurations of the magnetic area.

Each pair of N/S poles generates an autonomous and defined force which is not influenced by the operating conditions of the other adjacent poles.Therefore by counting the number of poles occupied by the clamped pieceit is possible to predetermine the force generated and consequently toe stablish the usable machine power with the relative machining parameters.

It's widely applied to attract workpieces in surface grinders, electric processing machine-tools, as well as in casting, drilling, planning and boring machines. Besides, it's used in accessory holders for processing centers and FMS systems.

Permanent-electro magnetic Chuck controller: There are one-way, two-way and four-way channels to be chosen in our company and we can design more multi-way controllers such as 8-way,16-way according to customers' requirements.

The standard series of chucks include more versions which have different performance characteristics. Capable of adapting to different operating needs, depending on the thickness. The surface condition (or the operating air gap) and the dimensions of the work piece to be clamped. The clamping force of each version depends on the different dimension types of poles and on the configurations of the magnetic area.

Each pair of N/S poles generates an autonomous and defined force which is not influenced by the operating conditions of the other adjacent poles.Therefore by counting the number of poles occupied by the clamped pieceit is possible to predetermine the force generated and consequently toe stablish the usable machine power with the relative machining parameters.