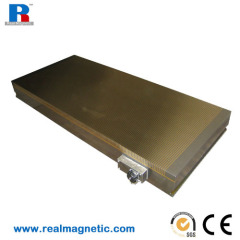

320*800 Permanent-electro Magnetic Chuck

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Magnetic Workholding, Quick Mould Clamping System, Electro Permanent Magnetic Chucks, Magnet Chuck, Injection Clamping System |

Product Detail

| Model No.: | DMEPC70 |

|---|---|

| Means of Transport: | Ocean |

| Brand name: | MaxMagnet |

| Chuck size: | 320*800 |

| Pole number: | 24 |

| Pole size: | 74*74mm |

| Magnetic force: | 750kg/pole |

| Function: | workholding |

| Control mode: | CNC |

| Magnetization output time: | 0.1--0.9S |

| Production Capacity: | 100sets/month |

| Packing: | wooden case |

| Delivery Date: | 30 days |

Product Description

magnetic chuck control

It's widely applied to attract workpieces in surface grinders, electric processing machine-tools, as well as in casting, drilling, planning and boring machines. Besides, it's used in accessory holders for processing centers and FMS systems.

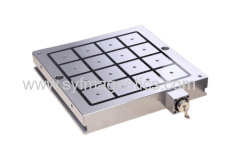

Models: Electro Permanent Magnetic Chuck, magneticchuck, ep-chuck,rectangle electro permanent magnetic chuck, permanentMagnetic Chuck, circular electro magnetic chuck, round electro permanentmagnetic chuck, grinding magnetic chuck, milling magnetic chuck,cncmagnetic chuck,etc.

Safety

Constant and concentrated force

No electric power supply during clamping

Ergonomic in operation

No dispersion of magnetic flux

No interference

Constant and concentrated force

No electric power supply during clamping

Ergonomic in operation

No dispersion of magnetic flux

No interference

Productivity

Easy and quick set-up

Drastic reduction in downtime

Higher stock-removal rates

Facilitated interaction with CAD/CAM systems

Improved finishing and greater accuracies

Easy and quick set-up

Drastic reduction in downtime

Higher stock-removal rates

Facilitated interaction with CAD/CAM systems

Improved finishing and greater accuracies