Quick Mold Clamping System For 1300T Multi-shot Injection with revolving platen

| Min. Order: | 1 set |

|---|---|

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Magnetic Workholding, Quick Mould Clamping System, Electro Permanent Magnetic Chucks, Magnet Chuck, Injection Clamping System |

Product Detail

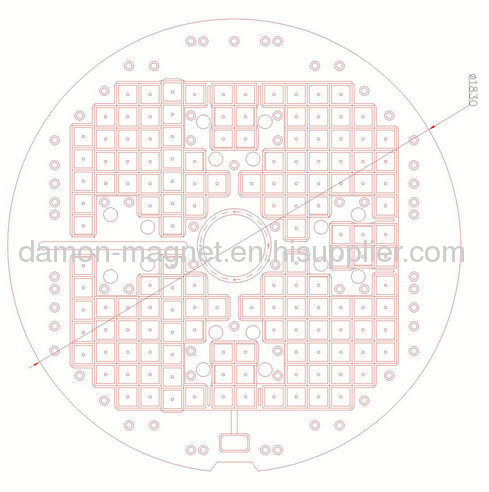

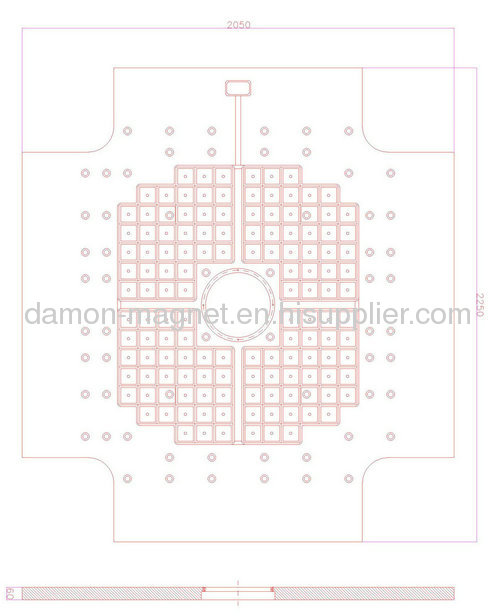

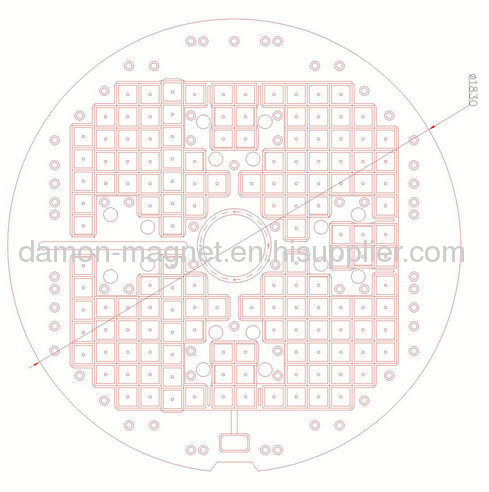

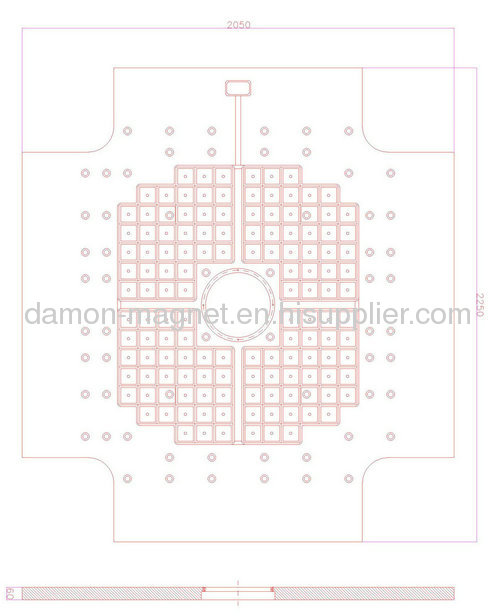

| Model No.: | DM-QMC70 |

|---|---|

| Brand name: | MaxMagnet |

| Chuck size: | 1830*1830mm |

| Pole number: | 280 |

| Pole size: | 74*74mm |

| Magnetic force: | 750kg/pole |

| Function: | mold clamping |

| Control mode: | Injection molding machine |

| Magnetization output time: | 0.1--0.9s |

Product Description

1. During the Mag phase the magnetic flux is short-circuited outside the magnetic surface, safely clamping the mold with a very limited magnetic depth, so as not to affect any internal part of the engaged mold.

2. Our systems simplify mould handling,especially for those large or heavy moulds. This meams your operators can work in total safety and your equipment and tooling is preserved against damage from loading operations.

3. Rapid mold change - saving more than 90% mold changing and installation time, suitable for the current high-speed competive era, promoting an enterprise competition ability, being fast, on-time delivery, reducing production cost, saving production time.

4. Supply specification:

• Permanent-electro magnetic modules, in steel monoblock, for fixed and moving platen, with centering ring.

• Fixing and ejectors holes, based on standard (EUROMAP / SPI / JIS).

• Electronic control unit, IP54 cabinet.

• Remote push-button for MAG/DEMAG cycle, with signal lamps and interlock key.

• Wiring cables: control unit-modules, interface and power supply connections.

•• Set of fixing bolts with nogs.

• Instruction book and CE certifications.

1300T Double coloured Injection Electric permanent magnetic quick mould change Systems

2. Our systems simplify mould handling,especially for those large or heavy moulds. This meams your operators can work in total safety and your equipment and tooling is preserved against damage from loading operations.

3. Rapid mold change - saving more than 90% mold changing and installation time, suitable for the current high-speed competive era, promoting an enterprise competition ability, being fast, on-time delivery, reducing production cost, saving production time.

4. Supply specification:

• Permanent-electro magnetic modules, in steel monoblock, for fixed and moving platen, with centering ring.

• Fixing and ejectors holes, based on standard (EUROMAP / SPI / JIS).

• Electronic control unit, IP54 cabinet.

• Remote push-button for MAG/DEMAG cycle, with signal lamps and interlock key.

• Wiring cables: control unit-modules, interface and power supply connections.

•• Set of fixing bolts with nogs.

• Instruction book and CE certifications.

1300T Double coloured Injection Electric permanent magnetic quick mould change Systems