Festo Model Pneumatic Air Pressure Regulator

| Min. Order: | 5 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 10000Sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Type: | Cabinet Air Conditioner |

| Brand Name: | SUPERMECH |

| metal bowl guard: | aluminum alloy |

| Housting: | zinc die-casting |

| Sealing: | NBR |

| Production Capacity: | 10000Sets/month |

| Packing: | 1. with our brand 2. with blank brand no logo 3.with client logo |

| Delivery Date: | 15-30Days |

Product Description

Prouduct name: Festo Type Pneumatic Air Regulator

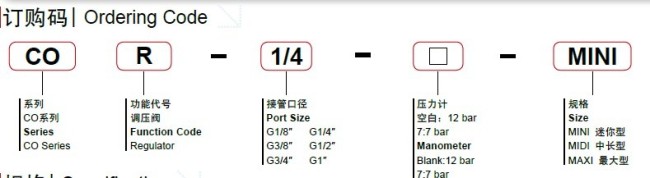

Model: COR

| Size | MINI | MIDI | MAXI | ||||||

| Medium | Filtered,compressed air (lubricated or unlubricated) | ||||||||

| Features of structure | MINI/MIDI:Diaphragm type regulator; MAXI:Piston regulator | ||||||||

| Mounting type | Pipe / Foot / Plate mounting | ||||||||

| Assembly position | Any | ||||||||

| Connection | G1/8 | G1/4 | G3/8 | G3/8 | G1/2 | G3/4 | G3/4 | G1 | |

| Standard nominal flow rate | OR-... | 800 | 1500 | 1700 | 3200 | 3500 | 3500 | 11000 | 11500 |

| OR-...-7- | 1000 | 1600 | 1800 | 3300 | 4000 | 4500 | 12000 | 12500 | |

| Primary pressure | 1~16bar | ||||||||

| Working pressure | 0.5~12bar / 0.5~7bar | ||||||||

| Temperature range | 0~60°C | ||||||||

| Materials information | Housing:Zinc die-casting;Sealing:NBR;Adjusting knob:POM | ||||||||

1. O series Feature

O series FRL is same style as Festo, it can get better effect after polishing treatment, so the texture of F.R.L body servicing with zinc alloy is more delicate.This advantage depends on the density of zinc is higher than Aluminum, so is the flow ability.The Max Adjustable Pressure of this series can reach 1.6bar.It is more ideal for high pressure system.

FRL use and maintenance

a. working medium to the use of clean and dry compressed air, and the air inside the pipe to prevent impurities into fully purge the system caused by the cylinder, valve malfunction, requiring lubrication piping systems in add lubricator is recommended to use lubrication oil is a transparent oil No. 1 (ISOVG32).

b. Normal system operation, to regularly check the air filter, lubricator work, and timely drainage (except automatic drain), refueling

c. Cylinder and valve when for long time not to use, pay attention to the minimum operating frequency of 1/30 days

d. Always check the operation of various pneumatic components, check the connection screws loose? Components for damage seal leakage phenomenon? Identify problems and timely treatment

e. Maintenance, be sure to turn off gas supply in advance, and the compressed air piping system maintenance operations can be carried out after emptying to prevent accidents

f. Component overhaul complete reassembly parts must be cleaned, and other impurities can not be brought within the system

brand packages:

1. with our brand SUPERMECH in products and boxes

2. with blank brand no logo

3.with client logo

Dear Mr/Ms,

Come to China, Come to SUPERMECH

We are factory of Pneumatic Cylinder and Pneumatic Fittings, air source treatment(FRL Combination), Solenoid Valve, if you are interested in our company, please contact us freely, We promise to reply email to you in 24 hours.

Contacts:

NINGBO SUPERMECH PNEUMATIC HYDRAULIC CO.,LTD.

Sales: Tracy zhang

Skype: tracy.zhang5

Tel: +86-574-88867713

Fax: +86-574-88865713

.jpg)