SCLF Standard Double Action pneumatic cylinder intake lock

| Min. Order: | 5 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 10000pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Brand Name: | SUPERMECH |

| rear end cap: | aluminum alloy |

| front end cap: | aluminum alloy |

| piston: | aluminum alloy |

| pipe material: | aluminum alloy |

| piston rod: | steel |

| Production Capacity: | 10000pcs/month |

| Packing: | cartons/pallets |

| Delivery Date: | 20-30days |

Product Description

Standard Double Acting Lock Type Pneumatic Air Cylinder airtacy type

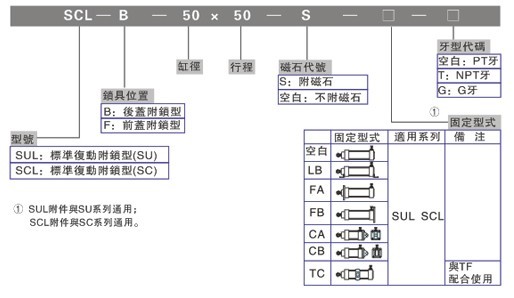

Model: SCLF

Odering code:

Dear Mr/Ms,

Come to China, Come to SUPERMECH

We are factory of Pneumatic Cylinder and Pneumatic Fittings, air source treatment(FRL Combination), Solenoid Valve, if you are interested in our company, please contact us freely, We promise to reply email to you in 24 hours.

1 pneumatic Cylinder using conditions

(1) Pneumatic cylinder using the system pressure, medium temperature should be consistent with the basic parameters of pneumatic cylinder models specified value table.

(2) The compressed air must be clean drive cylinder, less water, this circuit must be used in the gas manifold filter.

In order to lubricate the cylinder internal loop in the pneumatic system lubricator must be used (no oil lubrication cylinder can not)

Cylinder Installation

(1) cylinder should be checked before unpacking the cylinder for damage during transportation, nuts or threaded rod ends for loose connections, remove rust oil and protective cover (cap) before installation

(2) the cylinder piston rod cylinder installation should pay attention not withstand eccentric loads or lateral loads, should make the load axis line direction of movement of the piston rod consistent load for long stroke cylinder and piston rod connected to the best use of the V-type connector can be active or joint head. Whatever the cylinder base installation must ensure there is sufficient rigidity.

(3) When used in a horizontal cylinder block, use "three-point method" for testing. First, the piston rod connected to the load, when the piston rod is fully extended, to put a water level in the bar intermediate level observed situation; secondly in the intermediate position when the piston rod, the piston rod is in close proximity to the piston rod at the eye level to put a water level situation; Finally rod in the retracted position, should no other fresh phenomenon. Long-cylinder horizontal installation, in order to prevent the piston rod sagging, deformed cylinder shall be properly supported.

(4) Front and rear flange, tripod-mounted cylinder, fitted bolts should avoid direct exposure to pushing or pulling loads.

(5) Binaural using rear single cylinder or intermediate swing cylinder piston rod tip when connecting pin location should be the axis position with attachments in the same direction.

(6) Cylinder should be installed to use the no-load condition to run 2-5 times the working pressure, check whether the cylinder buckle portion anomalies.

(7) Cylinder speed. Velocity of the cylinder there are certain requirements, the pneumatic system must be installed one-way throttle. Generally cylinder horizontally mounted exhaust throttle speed is relatively stable. Vertical mounting cylinder intake air throttle valve when the speed of the cylinder connected to the first load, the speed adjusting valve to the middle of the adjustment range of the subsequent output pressure regulator valve, the cylinder when a predetermined speed close to the speed, can be determined for the tone then set pressure regulating valve available speeds (one-way throttle) for fine-tuning.

(8) With adjustable cushioning cylinder, running buffer before the first control valve fully open, and then gradually increase the damping until satisfied. Cushion needle adjustment knob clockwise increases the damping, damping knob counterclockwise decreases.

(9) With adjustable cushioning cylinder, running buffer before the first control valve fully open, and then gradually increase the damping until satisfied. Cushion needle adjustment knob clockwise increases the damping, damping knob counterclockwise decreases.