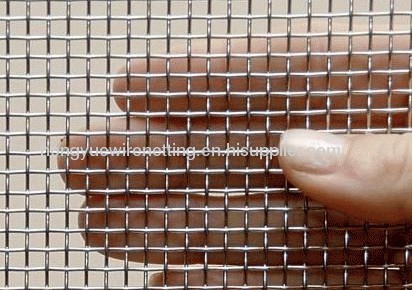

Galvanized Square Wire Netting

10.0~50.0 USD

| Min. Order: | 300 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 500 Square Meters Per Day |

| Place of Origin: | Hebei |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association |

Product Detail

| Model No.: | Q235 |

|---|---|

| Means of Transport: | Ocean |

| Application: | Others |

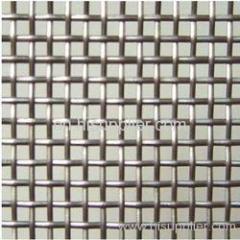

| Type: | Woven |

| Material: | Others |

| Brand Name: | BULL |

| Mesh Size: | at your request |

| Hole Shape: | Square |

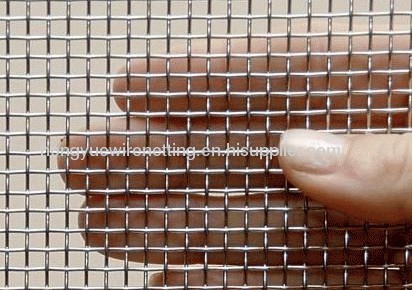

| Aperture: | 0.3--6.87mm |

| Wire Gauge: | 0.12--1.6mm |

| Production Capacity: | 500 Square Meters Per Day |

| Packing: | according to the customers' request |

| Delivery Date: | 20--25 days |

Product Description

Galvanized Square Wire Netting

Material

Galvanized iron wire, or stainless steel wire

Property

Packing

Standard square wire mesh

Hot-dipped galvanized after woven square wire mesh

Galvanized after woven square wire mesh

Galvanized before woven square wire mesh

Iron Square Wire Mesh

General Use

Galvanized hardware cloth is used for many industrial and commercial screening applications and is one of the most economical means of resisting rust and corrosion.

Applications include screens for vents, louvers, spark arrestors, finger guards, baskets, racks, trays, cages, dehydrators and miscellaneous sheet metal fabrications.

Processing

Processing

Processing

Hot dipped galvanized before or after weaving, electric galvanized before or after weaving.

| Mesh | Wire Dia.(mm) | Opening(mm) |

| 3 | 1.6 | 6.87 |

| 4 | 1.2 | 5.15 |

| 5 | 0.95 | 4.13 |

| 6 | 0.8 | 3.43 |

| 8 | 0.7 | 2.34 |

| 10 | 0.6 | 1.94 |

| 12 | 0.55 | 1.56 |

| 14 | 0.41 | 1.4 |

| 16 | 0.35 | 1.24 |

| 18 | 0.3 | 1.11 |

| 20 | 0.27 | 1 |

| 22 | 0.25 | 0.9 |

| 24 | 0.23 | 0.83 |

| 26 | 0.2 | 0.78 |

| 28 | 0.18 | 0.73 |

| 30 | 0.15 | 0.7 |

| 35 | 0.14 | 0.59 |

| 40 | 0.14 | 0.5 |

| 50 | 0.12 | 0.39 |

| 60 | 0.12 | 0.3 |

Property

Square Wire Mesh is made of selected low carbon iron wire with precision construction, uniform mesh, fine rust-resisting and durable function.

Packing

In rolls, wrapped with waterproof paper then covered with hessian-cloth. Special packing may be arranged if necessary.

Features

Sophisticated, mesh uniform, good corrosion resistance and sturdy.

Standard square wire mesh

Hot-dipped galvanized after woven square wire mesh

Galvanized after woven square wire mesh

Galvanized before woven square wire mesh

Iron Square Wire Mesh

General Use

Applications include screens for vents, louvers, spark arrestors, finger guards, baskets, racks, trays, cages, dehydrators and miscellaneous sheet metal fabrications.

.jpg)