Supply good quality WPC profile extruding machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1-3sets/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | HDPE Pipe Extrusion Machine, PC/PP/PE Plastic Hollow Board Production Line, PVC Sheet Extrusion Line (Plastic Machinery), Plastic Machinery, PE Pipe Plastic Machinery |

Product Detail

| Model No.: | BAX SJZ |

|---|---|

| Means of Transport: | Ocean, Land |

| Plastic Type: | PP/PE |

| Use: | Waste Plastic Crusher |

| Shaft Design: | Others |

| Brand Name: | BENICE |

| Power: | 37kw |

| Capacity: | 180-300kg/h |

| PRODUCTION NAME: | WPC PROFILE EXTRUDING MACHINE |

| PROCESSING TYPE: | PLASTIC WOOD EXTRUDER |

| MATERIAL: | PE+WOOD POWDER |

| INVERTER: | ABB BRANDS |

| TEMPERATURE CONTROLER: | RKC BRANDS |

| Production Capacity: | 1-3sets/month |

| Packing: | packing in film |

| Delivery Date: | 45 working days |

Product Description

WPC profile extrusion machinery total line

WPC moulds

WPC moulds

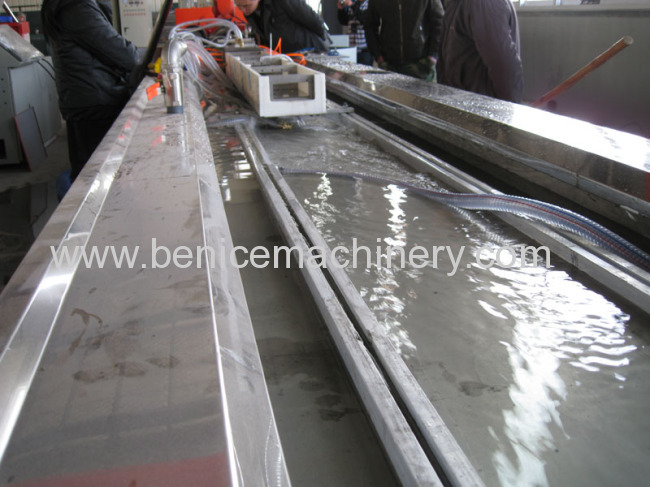

Water calibration cooling tank

Water calibration cooling tank

WPC profile extruding machine Production introduction:

A) This production line is mainly used to produce WPC profile, such as Ceiling, Deck, Floor, Cornice, Plank, Windows, Door frame and board and etc.

(B) WPC profile extruding machine Feature:

1. Conical twin-screw extruder, suitable for processing WPC raw materials.

2. Changing the moulds to produce many kinds of different profiles.

3. Auxiliary machine: Mixing unit, Mould, Vacuum calibration table, Haul-off machine, Cutter and Stacker.

4.can using recycling materials, good for environment

(C)WPC profile extruding machine technical data:

Extruder | SJZ51/132 | SJZ55/110 | SJZ65/132 | SJZ80/156 | SJZ92/188 |

Main Motor Power | 18.5kw | 30kw | 37kw | 55kw | 110Kw |

Production capacity | 80-100kg/h | 100-180kg/h | 150-200kg/h | 200-300kg/h | 550-700kg |

Keywords: wpc profile production line, wpc window and door profile production line, wpc window and door proflie extrusion line, profile extrusion line, wpc window and door profile making machine