PERT floor heating pipe extruding machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10sets/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | HDPE Pipe Extrusion Machine, PC/PP/PE Plastic Hollow Board Production Line, PVC Sheet Extrusion Line (Plastic Machinery), Plastic Machinery, PE Pipe Plastic Machinery |

Product Detail

| Model No.: | SJ65 |

|---|---|

| Means of Transport: | Ocean, Land |

| Plastic Type: | Others |

| Use: | Others |

| Shaft Design: | Single |

| Brand Name: | BENICE |

| Power: | 30KW |

| Capacity: | 80-160KG/H |

| PROCESSING TYPE: | PIPE EXTRUSION LINE |

| MATERIAL: | PERT |

| EXTRUDER TYPE: | SINGLE SCREW |

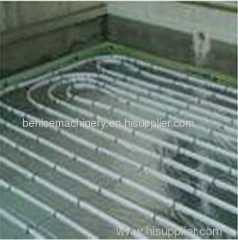

| PIPE APPLICATION: | FLOOR HEATING PIPE, WATER PIPE |

| PIPE DIAMETER: | 16 20 25MM |

| FEEDER: | AUTOMATIC FEEDING |

| INVERTER: | ABB BRANDS |

| CONTACTOR: | SIEMENS BRANDS |

| REALY: | SIEMENS BRANDS |

| L/D: | 25:1 28:1 30:1 33:1 |

| Production Capacity: | 10sets/month |

| Packing: | packing in film or wood case |

| Delivery Date: | 30 working days after 30% down payment |

Product Description

Description of PERT floor heating pipe production line:

Production introduction:

PERT floor heating pipe production line is mainly used for production of agricultural water supply, building water supply, central heating systems, solar water heating systems and so on. The unit from the main extruder, high pressure head, vacuum forming table, high-speed traction machine, cutting machine, no crumbs, duplex coil machine and so on. Single screw extruder and tractor adopts imported frequency control devices, vacuum pump and traction motors are made of high quality products.

1. Put PE-RT material and other assistant material into the mixer and mixing the material symmetrically.

2. Feed into the hopper, at the same time heat extruder and keep the temperature, and the material is melt and plasticizing by extruder.

3. Then extruded by die and head and goes into vacuum calibrating dia. Device, and cooling and calibrating dia.

4. Then draw-off by draw-off machine, then printing word by ink jet printer, then put into automatic cutter to finish the automatic cut according to preestablishing length and stacking into the shelf.

5. And the eligible product is packed and put into storeroom, and inferior product is crushed and recycled.

PERT floor heating pipe production line Main Material

1. PERT

2. Venter material and color material

3. Other assistant material

Note: We will provide our customers with material prescription, material type and relative technical document after signing contract.

Single screw extruder for PERT floor heating pipe machine specificaions

| SJ65/33 single screw extruder specification | ||

| Screw L/D | 28:1 30:1 33:1 | |

| Screw and barrel material | 38CrMoALA | |

| Motor power | 30kw | |

| Extrusion capacity | 80-180kg/h | |

| Control systerm | Frequency speed control | |

| Electrical control parts | ABB inverter, RKC temperature controller,Siemens contactor,realy | |

| Suitable pipe diameter | 16, 20, 25mm also can produce pe/pp pipes | |

| Cooling type | Fan cooling systerm | |

PERT FLOOR HEATING PIPES APPLICATION

.gif)