PE composite pipe production line

50000.0~100000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 3-5sets/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | HDPE Pipe Extrusion Machine, PC/PP/PE Plastic Hollow Board Production Line, PVC Sheet Extrusion Line (Plastic Machinery), Plastic Machinery, PE Pipe Plastic Machinery |

Product Detail

| Model No.: | SJ |

|---|---|

| Means of Transport: | Ocean, Land |

| Plastic Type: | PP/PE |

| Use: | Plastic Pipe Crusher |

| Shaft Design: | Single |

| Brand Name: | benice |

| Power: | 55KW |

| Capacity: | 200Kg/h |

| PROCESSING TYPE: | COMPOSITE PIPE EXTRUDER LINE |

| MATERIAL: | PE/PERT/ALUMINUM |

| Production Capacity: | 3-5sets/month |

| Packing: | packing in film or wood case |

| Delivery Date: | 40 working days |

Product Description

PE-AL-PE composite pipe production line

Two kind welding process:

1.ultrasonic lap seam welding.co-extrusion forming.

2.butt-joint argon-arc welding,welding seam closegained and smooth.

controlling center adopting computer control system of Austria B&R company programmable computer.

long-distance closed loop control automatically the process of the process of the speed

This line fabricates aluminium and plastic composite pipes,aluminium pipes ultrasonic welded,co-extrusion shapong ,the products are widely used for conveying cold and hot running water,acid,alkali,salt liquid ,gas ,oxygen,compressed air,etc.

The main technique parameter:

| Pipe diameter | Φ16-Φ32 |

| Foil width | 0.2-1mm |

| Line speed | 3.5-11m/min |

| Output per year | more than 1-3.5million meter |

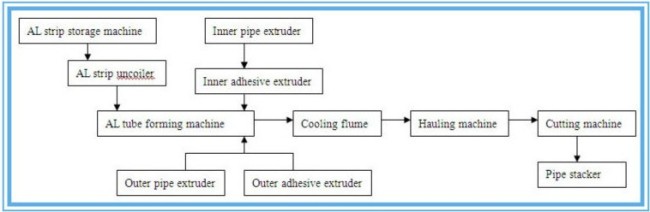

THE PRODUCTION LINE PROCESS:

THE PIPE STRUCTURAL FEATURES:

.gif)