Plastic PE board production line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 2sets/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | HDPE Pipe Extrusion Machine, PC/PP/PE Plastic Hollow Board Production Line, PVC Sheet Extrusion Line (Plastic Machinery), Plastic Machinery, PE Pipe Plastic Machinery |

Product Detail

| Model No.: | SJ120 |

|---|---|

| Means of Transport: | Ocean, Land |

| Plastic Type: | PP/PE |

| Use: | Waste Plastic Crusher |

| Shaft Design: | Single |

| Brand Name: | BENICE |

| Power: | 55KW |

| Capacity: | 300KG/H |

| PROCESSING TYPE: | PE BOARD MACHINE |

| EXTRUDER TYPE: | SJ90 SINGLE EXTRDER |

| MATERIAL: | PP PE PELLETS |

| INVERTER: | ABB BRANDS |

| AUTOMATIC GRADE: | SEMI-AUTOMATIC |

| BRAND NAME: | BAX |

| Production Capacity: | 2sets/month |

| Packing: | packing in film |

| Delivery Date: | within 35 working days |

Product Description

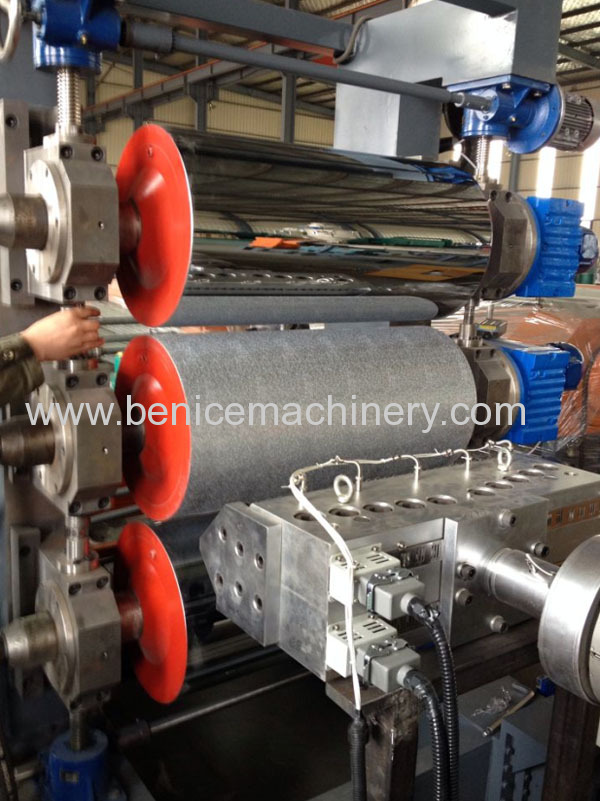

PE boards production line

Board thickness:1mm-30mm

Board width:500mm-1800mm

SJ series Single screw extruder

Max.capacity:400kg/h

PP/PEboard production line features:

High performance single screw extruder

Automatic feeder and dryer system

ABB inverter,RKC temperature controler,Siemens contactor and realy

Plast board machinery for pp pe boards Process flow:

Single screw extruder→hydraulic filter→mold→three-roller calender→cooling bracket→edge cutting device→haul-off→transversal cutter→stacker(three roller cooling device,transmission device,length measuring device unit)

PE board production line Description:

1,The screw is designed of special mixing function and high plasticization capacity.

2,The special designed T-type mold ensures a precise control to the thickness of the board.

3,The accurate temperature control (±1) can precisely control the plasticization process, thickness and smoothness of board.

4,The three-roller calendar adopts horizontal, vertical or 45°tilt type installation, with up-down lifting mode.

5.The thickness of board is controlled by screw and pressing roller in two directions.

6.The separate roller temperature control system can precisely control the pressing roller temperature to ensure a even thickness.

7.Cutting machine can cut the sheet with accurate length and quantity.

8.The winding device uses big torque motor, can freely regulate the winding speed and tension.

9.The automatic meter countering device can pre-set the length of the product.

10.PE board machinery produced by Benice company has advantages of durable using life, nice after-selling service,long guarantee time,ect.

PE plastic board production line Technical parameter:

Mode | Single-layer PP sheet production line | Multi-layer PP sheet production line |

SJ-120/33 | SJ-120/33,SJ65/33 | |

Product width | 500-1800mm | 500-1800mm |

Product thickness | 1-30mm | 1-30mm |

Main motor power | 132kw | 132kw/45kw |

Extrusion capacity | 350kg/h | 400kg/h |

Customer was checking products before delivery

.gif)