PVC cable trunking manufacturing plant

20000.0~50000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | at least 2sets/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | HDPE Pipe Extrusion Machine, PC/PP/PE Plastic Hollow Board Production Line, PVC Sheet Extrusion Line (Plastic Machinery), Plastic Machinery, PE Pipe Plastic Machinery |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Plastic Type: | PVC |

| Use: | Others |

| Shaft Design: | Double |

| Brand Name: | BENICE |

| Power: | 37KW |

| Capacity: | 80-180KG/H |

| USING EXTRUDER TYPE: | SINGLE SCREW OR TWIN SCREW EXTRUDER |

| PRODUCTION NAME: | PVC TRUNKING EXTRUSION LINE |

| ELECTRICAL CONTROL PARTS: | ABB CONVERTER,RKC TEMPERATURE |

| PRODUCTION LINE COLOR: | SHOWED AS PICTURE OR ACCORDING TO CUSTOMERS' REQUIRES |

| Production Capacity: | at least 2sets/month |

| Packing: | pvc trunking production line packing in normal film |

| Delivery Date: | pvc trunking production line 30working days |

Product Description

Introduction of PVC cable trunking profile manufacturing plant:

PVC cable trunking profile production line also called pvc cable duct profile productionline, pvc wire trunking profile production line,etc.

PVC cable trunking manufacturing plant equipments list:

PVC cable trunking manufacturing plant equipments list:

BAXSJ1. thisprofile production machine line extruder: adopting single screw extruder, uniquedesigned screw, realizing quick plasticizing time, good compounding andexcellent plasticization.

BAXSJ2. profileextruder gearbox: adopting super quality gear box and reducer, with nice outline, stable running, low noise and long using time.

BAXSU3.extruding barrel temperature controlling system: adopting cast aluminum heaterswith stainless steel covers, wind cooling system, ensuring good features ofcooling and heating, precision temperature controlling.

BAXSJ4. screwand barrel: screw-core installing with internal temperature controlling system,barrel equipped with vacuum degassing system, can get rid of the waste gas fromthe raw material which can guarantee super quality of the products,make profilesurface smooth and shapely.

BAXSJ5. drivingsystem: adopting A.C motor, using ABB inverters which provide stable torqueoutput and various high speed.

BAXSJ6. vacuumcalibrating tank: with two aluminum racks, to install various profile extrudingdies, the main body of the tank make of stainless steel, long servicetime.

BAXSJ7. haul-offmachines: 2 caterpillar haul-off machines are provided to manufacture differentwidth of profiles, haul-off speed governed by the ABB inverter.

BAXSJ8. cuttingunit: saw cutting, profile cutting length can be adjusted, with dust collectionsystem.

BAXSJ9. stakingunit: automatic overturning system, can freely fix the length of theprofile.

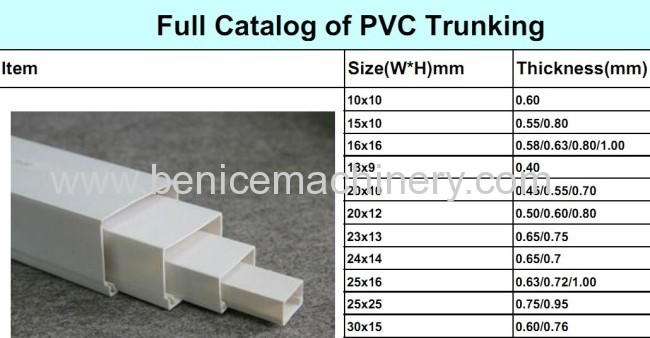

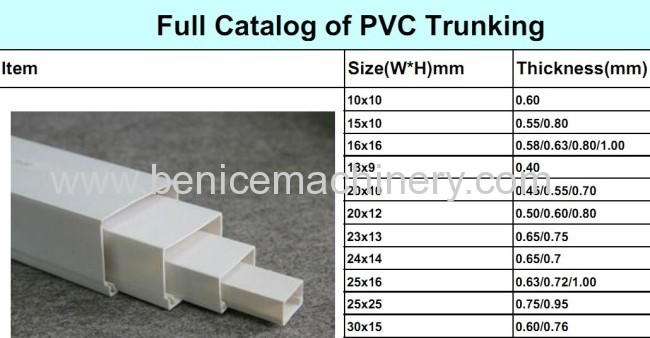

PVC cabletrunking sizes: 10*10,15*10,16*16

We canmake machines which produce different sizes calbe trunking, any needs about thepvc cable trunking extrusion machine, contatct me skype is benicexiaofei