PP film crushing and washing machine line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 3-5sets/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | HDPE Pipe Extrusion Machine, PC/PP/PE Plastic Hollow Board Production Line, PVC Sheet Extrusion Line (Plastic Machinery), Plastic Machinery, PE Pipe Plastic Machinery |

Product Detail

| Model No.: | BAX |

|---|---|

| Means of Transport: | Ocean, Land |

| Plastic Type: | PP/PE |

| Use: | Film Crusher |

| Brand Name: | BENICE |

| Power: | 37KW |

| Capacity: | 300KG/H |

| PROCESSING TYPE: | PLASTIC RECYCLING MACHINE |

| MATERIAL: | PP PE FILM |

| POWER SUPPLY: | 3-PHASE 380V 50HZ |

| Production Capacity: | 3-5sets/month |

| Packing: | packing in film |

| Delivery Date: | within in 40working days |

Product Description

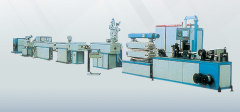

PP film crushing and washing machine line

The system is muture production with many years, aiming at a variety of films with different states in the garbage, especially the stretch film, sheet, thick film etc are difficult to dry. mail is fair at benicemachinery dot com skype is benicexiaofei Combined with the features of films, we design the proposal to the save energy and meet the requirement. According to the actual material state, we introduce the advanced technology from domestic and abroad, the output is 200-2000kg/h, the detail proposal is made by actual material state.

Film washing machine for PE PP bottles/bags/sheet/film

components:

1. belt conveyor

2. crusher

3. screw feeder

4. scrub washer

5. deposit and float machine

6. dewatering machine

7. drying pipes

8. transition silo

the whole line is automatically controlled from feeding to drying.

PE, PP film, bottles, bags, woven bags, sacks, and such materials can be washed and recycled in this machine line.

output capacity: 200-300kg/h, 500-600kg/h, 600-800kg/h, 1500-2000kg/h.

some special design can be met according to customers requirements

PE PP film crushing and washing line (capacity: 200-2000 kg/hr):

No. | Equipment Name | Total Power | Quantity | Comments |

1 | Belt Conveyor | 1.1-4.4kw | 1-2 set | |

2 | Crusher | 30-150kw | 1-2 set | |

3 | Screw Feeder | 2.2-4kw | 1 set | According to particular condition |

4 | Screw Feeder | 1.5-4kw | 1 set | |

5 | Film washing tank | 5-8.1kw | 1 set | According to particular condition |

6 | Screw Feeder | 1.5-4kw | 1 set | According to particular condition |

7 | Friction washing machine | 15-55.75kw | 1-2 set | |

8 | Film washing tank | 3-5.9kw | 1 set | |

9 | Screw feeder | 1.5-4kw | 1 set | |

10 | Dewatering machine | 45-160kw | 1 set | |

11 | Drying system | 33-51kw | 1 set | |

12 | Storage silo | 0.5-2m3 | 1 set | |

13 | Control System | 1. Using ABB Brand Convetor | 1 set |