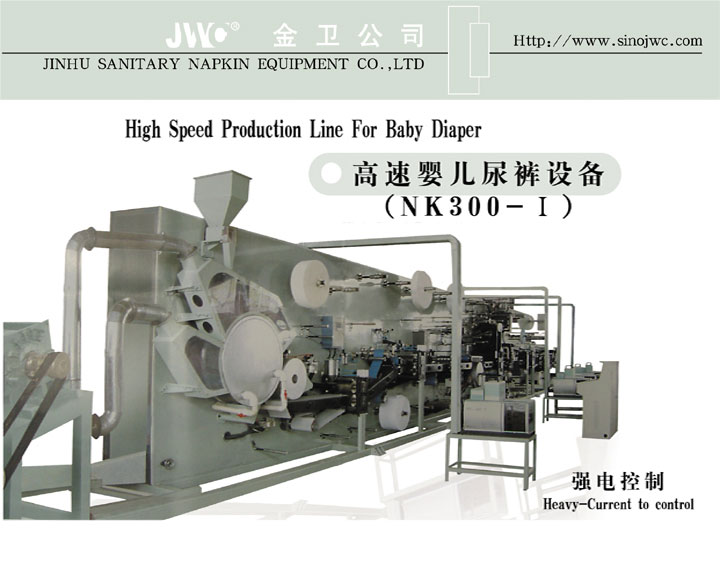

Baby Diaper Production Line

| Payment Terms: | T/T |

|---|---|

| Place of Origin: | Fujian |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | HX-350 |

|---|---|

| Packing: | wooden pallet |

| Delivery Date: | 60 working days |

Product Description

Function and configuration

1.Model explanation:

350B: basic function model;

350C: raw material frequency conversion automatically replace roll, constant tension control, production is more stable.

350D: half servo model, automatically replace roll, constant tension control, change size intelligently.

2.Product specification: 4 sizes, S,M,L,XL(specify according to client)

3.Design according to Europe CE standard, electric component has CE or UL certificated, equipped with safety door and emergency stop, etc safety device.

4.Equipment structure is firm and reasonable, accessories is processed well, main parts which is bought outside adopt internationally known brand.

5.Optional configuration: a: full servo control stacker. B: full automatic bagging sealing machine.

Main technical parameter:

Main technical parameter:

1.Product specification: 4 sizes, S,M,L,XL;

2.Designed speed: 400 pieces/minute;

3.Stable production speed: 250-400 pieces/minute(vary according to configuration)

(subject to M size, exclude glue machine factor)

4.Power Supply: 380V 50HZ

5.Machine capacity: about 130Kw(don't include Glue Machine power)

6.Product finished product ratio: ≥97%( exclude glue machine trouble and splicing material factors)

7.Product grams weight deflection: ±5%

8.Weight(including pulverizer): about 35 tons.

9.Machine running direction: face machine, run from Left to Right(or specify by client)

10.Machine color: dark blue color;

11.Machine size: (Length × width ×height): about 20 M x 2.2 M x 2.9 M (exclude crusher).